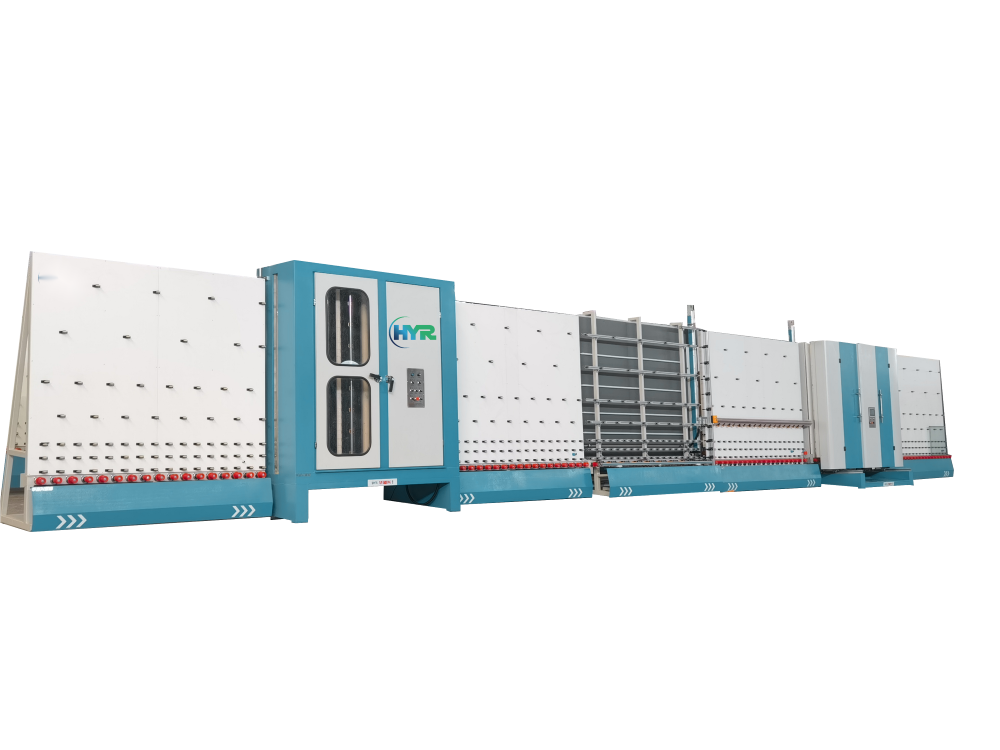

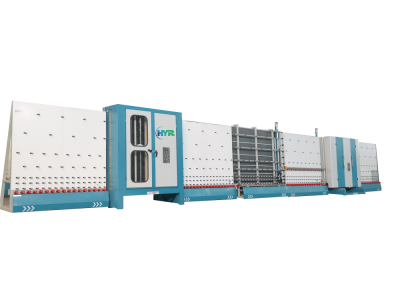

Customizable Hollow Glass Production Line

The main features of this glass washing machine include the use of stainless steel and corrosion-resistant materials for the wash areas, three pairs of independently operable brushes with adjustable spacing, and CNC automation programming. It is capable of producing double and triple glazed hollow glass, as well as long glass with secondary plate pressing. The machine offers both automatic and manual operation for ease of use. It features exclusive point adjustment technology for plate pressure and an automatic plate pressure maintenance function. A circulating hot air drying section enhances cleaning speed and reduces noise, while high-density soft brushes clean various types of LOW-E and coated glasses. The machine is equipped with an advanced intelligent cleaning system and can be customized for forward and reverse directions based on glass travel. Additionally, it offers customizable on-board inflation functions, including PW-C (external closure inflation) and PW (external closure).

Product Advantages:

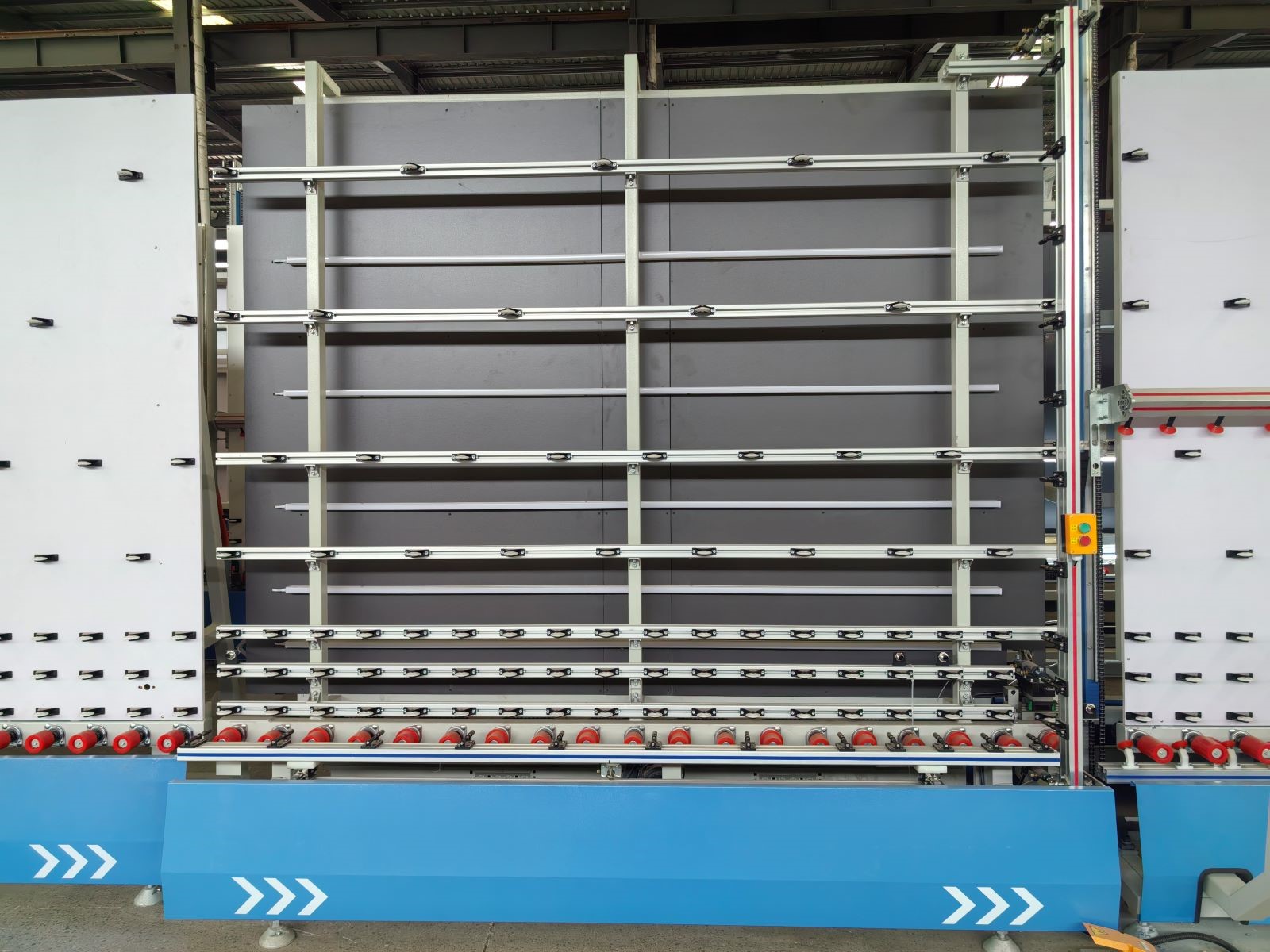

**Robust and Accurate Washing Segment:**

- Crafted with meticulous attention to detail using stainless steel and anti-corrosive materials, the washing segment is designed for enduring durability and steadfast reliability. It is equipped with three pairs of brushes that function independently and can be fine-tuned for the perfect spacing. These brushes are driven by CNC automated programming, ensuring a high standard of accuracy and efficiency throughout the cleaning procedure.

**Versatile Glass Manufacturing Capabilities:**

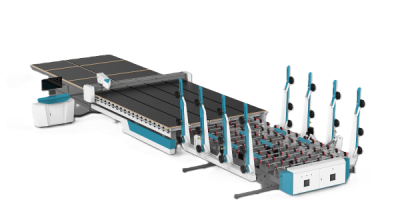

- Engineered for the production of both double-glazed and triple-glazed insulated glass units, this machine also has the capability to handle extended glass panels. It offers the flexibility to operate in either an automatic or manual mode, suiting various user inclinations and production demands. The machine's pressing plate incorporates exclusive point adjustment technology, complemented by an automatic maintenance feature to keep the pressing system in optimal working order.

**Efficient Drying and Smart Cleaning System:**

- A pivotal feature of the machine is the hot air recirculation drying section, which enhances cleaning efficiency, guarantees thorough drying, and operates with minimal noise. The machine is supplied with high-density soft brushes suitable for cleaning an array of glass types, including LOW-E and coated varieties. An advanced smart cleaning system is integrated into the machine to ensure peak performance.

**Configurable Movement Direction and Inflation Settings:**

- The machine allows for customization of its travel direction, enabling it to move forward or in reverse, which is especially beneficial for aligning with specific glass trajectories. Moreover, the machinery can be tailored to include a panel inflation option, available in two setups: PW-C with externally sealed inflation and PW with externally sealed inflation, thereby increasing the machine's flexibility and adaptability for various production settings.

Technical Parameters

Voltage | 3P/380V/50Hz | Maximum glass size | 2000×2500mm |

Total power | 28KW | Maximum thickness of insulating glass | 60mm |

Washing speed | 0-13m/min | Air consumption | 1m³/min |

Maximum working speed | 50m/min | Dimension | 18200×2800×2920mm |

Minimum glass size | 300×450mm |

Currently, our offerings are shipped to a diverse range of countries including the USA, Kazakhstan, South Korea, Singapore, Thailand, Vietnam, the Philippines, Australia, the UAE, South Africa, and India, where they have garnered an international reputation.