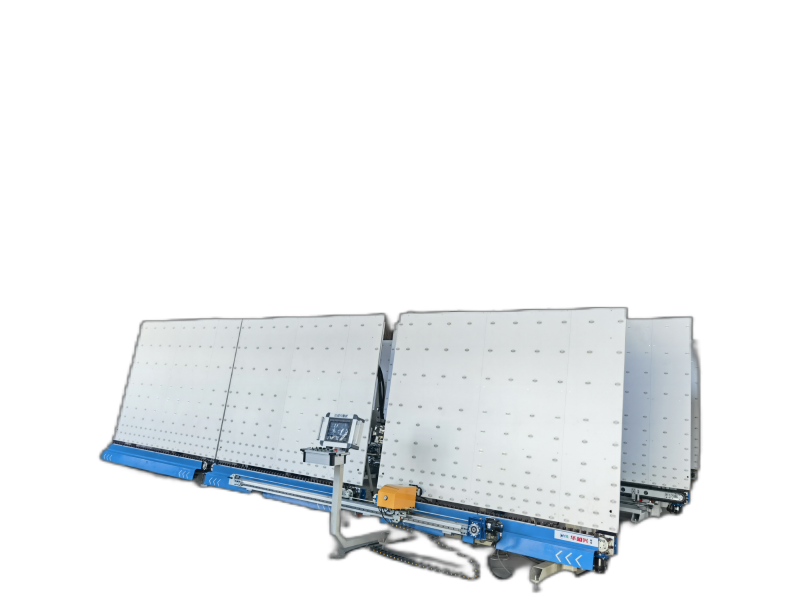

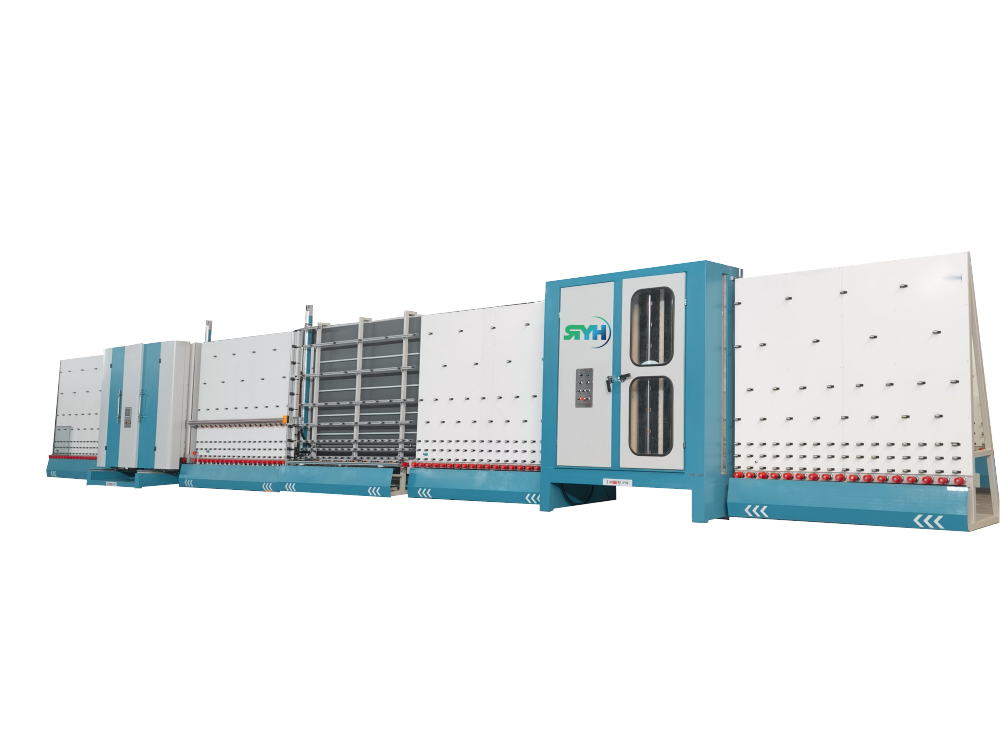

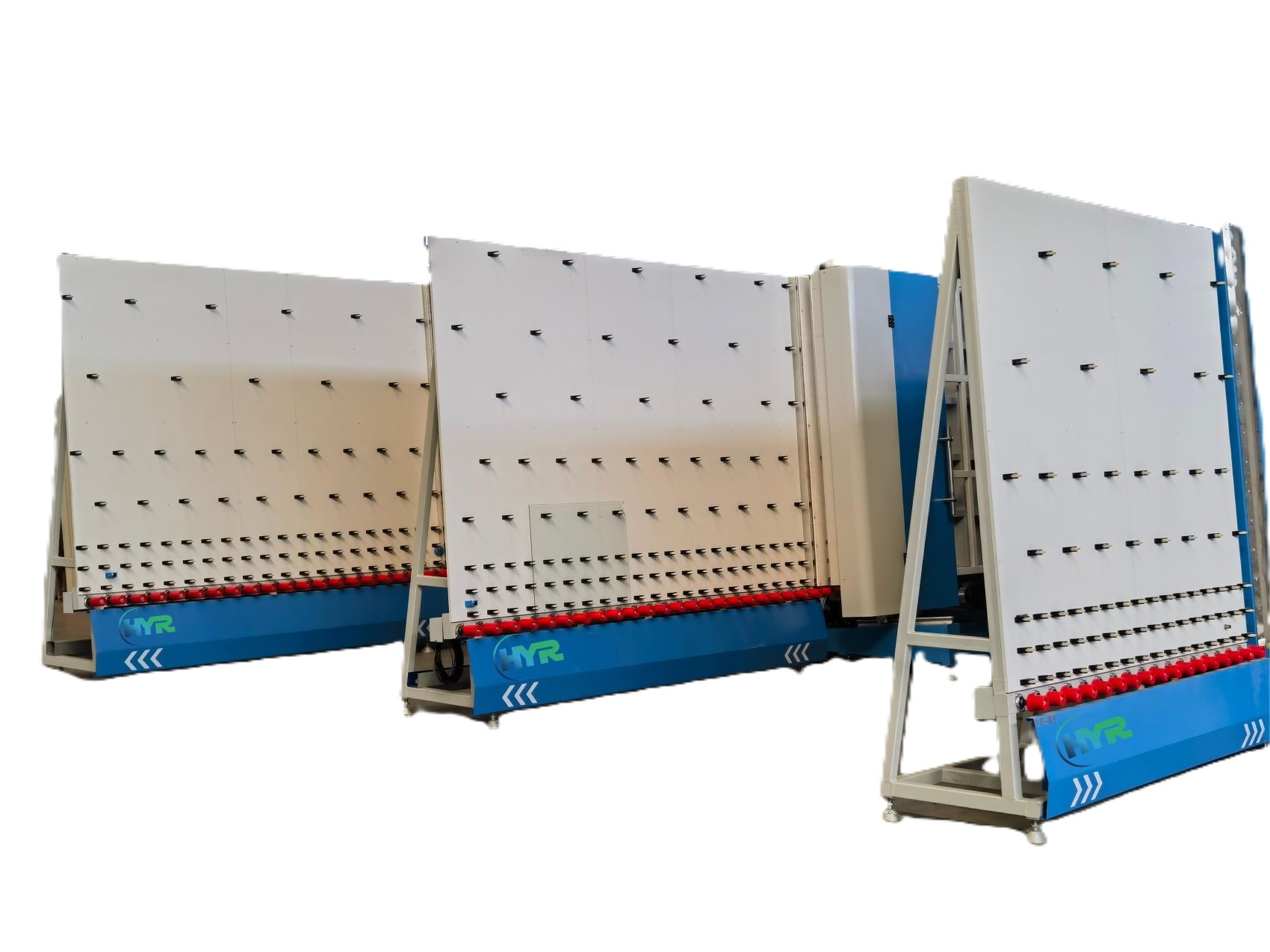

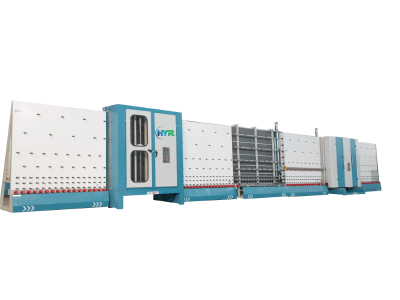

Large-Scale Integrated Hollow Glass Production Machine

MAIN FEATURES

Wash area and wash areas ucing stainless steel and corrosion-resistant materials,three pairs of independent operation brush,brush spacing is adjustable,using CNC automation program runs;

1. Can produce double glass and three glass hallow glass,long glass,long glass can be secondary plate pressure; Automatic or manual operation,easy to operate;

2. Plate pressure with exclusive point adjustment technology,and with automatic plate precsure maintenance function;

3. Circulating hot air drying section,improve the cleaning speed,making it dry reduce noise; All use high-density soft brush,can clean all kinde of LOW-E glaos,coated glaos;

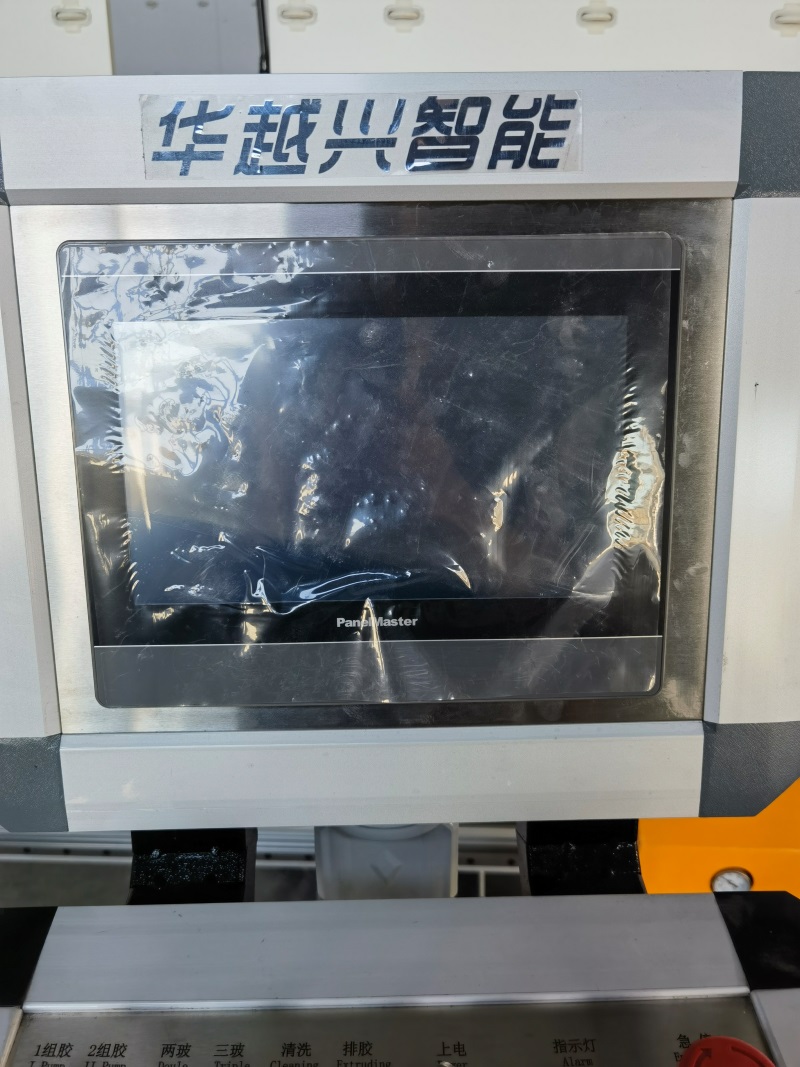

4. The machine is equipped with an advanced intelligent cleaning system;

5. Customizable forward and reverse direction of the device according to the direction of travel of the glass.

6. Customizable in board inflation function equipment,PW-C(external closuretinflation),PW(external closure).

Hua Yuexing Automation Technology (Jinan) Co., Ltd. is broadly speaking engaged in global change enterprise and belongs to Hua Yuexing Intelligent Equipment Group. The employer is positioned in Jinan High-tech Zone China (Shandong) Pilot Free Trade Zone; As a complete technological know-how company integrating scientific research, production, income and testing, Huayuexing has developed into a expert producer of glass tools in China, whose merchandise cowl the glass industry, rock plate enterprise processing equipment, doorways and Windows industry, agricultural equipment and different deep processing equipment.

MAIN FEATURES

- Automated Material Handling: The machine efficiently handles the loading of glass sheets and the unloading of completed insulating glass units, minimizing manual intervention and the risk of damage.

- Superior Butyl Extrusion Process: Equipped with a high-grade butyl extruder that guarantees tight and resilient seals, enhancing the unit's insulating capabilities.

- Accurate Spacer Bar Placement: Mechanized precision for inserting spacer bars, maintaining even spacing and facilitating gas filling processes.

- Automated Gas Injection: Features a state-of-the-art gas filling station designed for the injection of argon or other inert gases to boost thermal efficiency.

- Advanced Sealing Mechanism: Implements cutting-edge technology for applying both primary and secondary seals, ensuring durable insulation characteristics.

- Built-in Curing Oven: A dedicated curing oven is integrated for fast and even curing of sealing materials.

- Automated Quality Check and Packaging: The system includes an automated inspection process, followed by secure and streamlined packagin processing equipment, doorways and Windows industry, agricultural equipment and different deep processing equipment.

TECHNICAL PARAMETERS

Voltage | 3P/380V/50Hz | Maximum glass size | 2500×2500mm |

Total power | 32KW | Maximum thickness of insulating glass | 60mm |

Washing speed | 0-13m/min | Air consumption | 1.5m³/min |

Maximum working speed | 50m/min | Dimension | 22400×2800×3480mm |

Minimum glass size | 300×450mm |