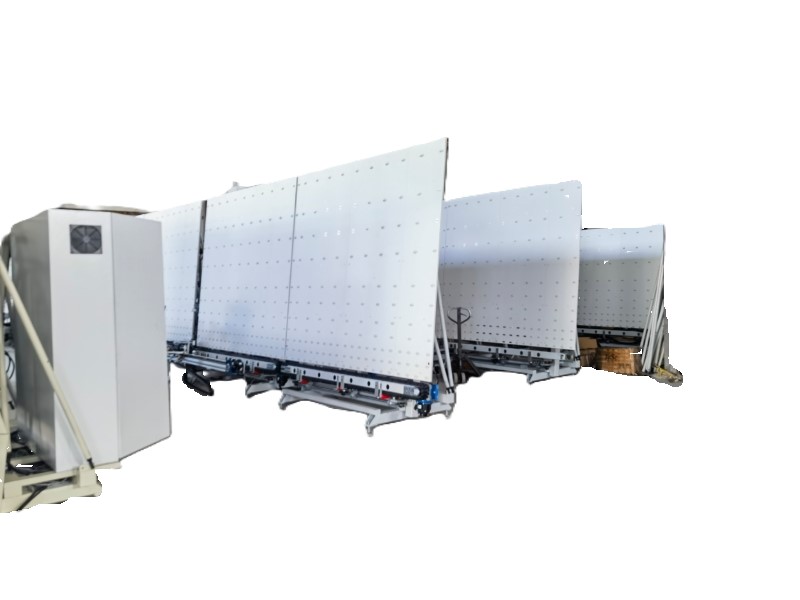

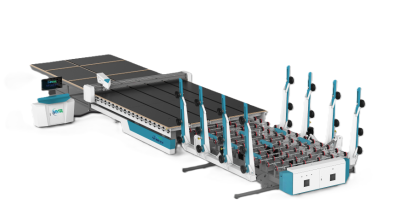

Vertical Insulting Glass Production Line for Fire-Resistant

Key Features:

Wash Area Construction: The wash area is crafted using stainless steel and corrosion-resistant materials, housing three pairs of independently operating brushes with adjustable spacing, all operated by a CNC automation program.

Glass Processing Capability: The machine is capable of producing double and triple hollow glass, as well as extended long glass. It offers secondary plate pressing for long glass and can be operated automatically or manually for ease of use.

Plate Pressure Technology: Features exclusive point adjustment technology for plate pressure, complete with an automatic plate pressure maintenance function for consistent performance.

Drying System: The hot air circulation drying section enhances cleaning speed and reduces noise by ensuring quick drying. It is equipped with high-density soft brushes suitable for cleaning various types of LOW-E and coated glass.

Intelligent Cleaning System: The machine is fitted with an advanced intelligent cleaning system for optimized cleaning efficiency.

Customizable Operation: The device's forward and reverse direction can be customized based on the glass travel direction for flexibility.

Inflation Function Customization: The equipment can be customized with an on-board inflation function, available in models PW-C (external closure inflation) and PW (external closure).

Product Details:

This glass processing machine boasts a range of sophisticated features designed for efficiency and versatility. The wash area, constructed from stainless steel and anti-corrosive materials, includes three pairs of independently operating brushes with adjustable spacing. These brushes are controlled by a state-of-the-art CNC automation program, ensuring precise and consistent cleaning.

The machine's capabilities are extensive, with the ability to produce double and triple hollow glass as well as extended long glass. It provides secondary plate pressing for long glass and offers both automatic and manual operation modes for user convenience. The drying system features hot air circulation that not only speeds up the cleaning process but also reduces noise, and the use of high-density soft brushes allows for the gentle cleaning of various LOW-E and coated glass types.

For added customization, the machine is equipped with an advanced intelligent cleaning system and allows for the adjustment of the device's forward and reverse direction based on the glass travel direction. Additionally, the equipment can be tailored with an on-board inflation function, available in PW-C (external closure inflation) and PW (external closure) models, providing further adaptability to meet specific production needs.

TECHNICAL PARAMETERS

Voltage | 3P/380V/50Hz | Maximum glass size | 2500×2500mm |

Total power | 32KW | Maximum thickness of insulating glass | 60mm |

Washing speed | 0-13m/min | Air consumption | 1.5m³/min |

Maximum working speed | 50m/min | Dimension | 22400×2800×3480mm |

Minimum glass size | 300×450mm |