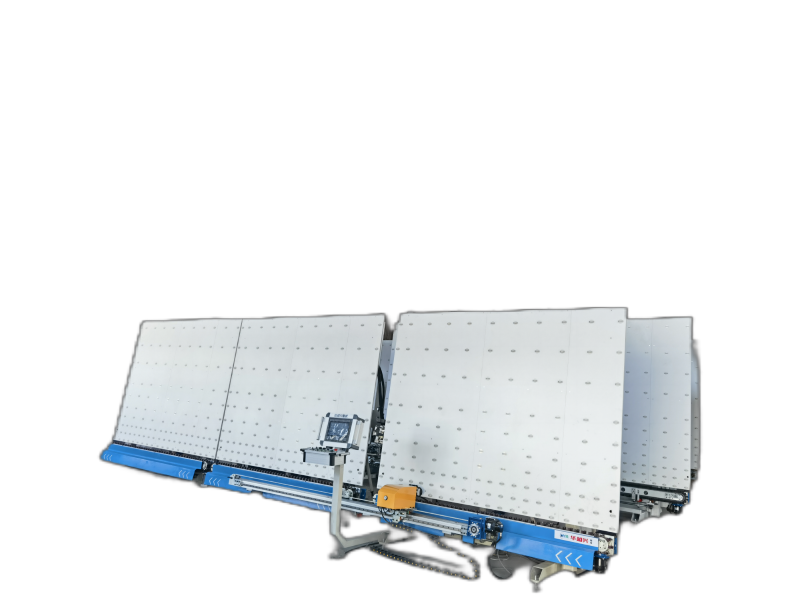

Recommend Double Glazed Glass Manufacturing Machinery

MAIN FEATURES

Wash region and wash areas the usage of stainless metal and corrosion-resistant materials, three pairs of impartial operation brush, brush spacing is adjustable, the usage of CNC automation software runs;

1.Can produce double glass and three glass hallow glass, lengthy glass, lengthy glass can be secondary plate pressure; Automatic or guide operation, effortless to operate;

2.Plate stress with unique factor adjustment technology, and with automated plate presure protection function;

3.Circulating warm air drying section, enhance the cleansing speed, making it dry minimize noise; All use high-density gentle brush, can easy all sort of LOW-E glasses, covered glasses;

4.The desktop is geared up with an superior sensible cleansing system;

5.Customizable ahead and reverse course of the machine in accordance to the route of tour of the glass.

Customizable in board inflation characteristic equipment, PW-C(external closure inflation), PW(external closure).

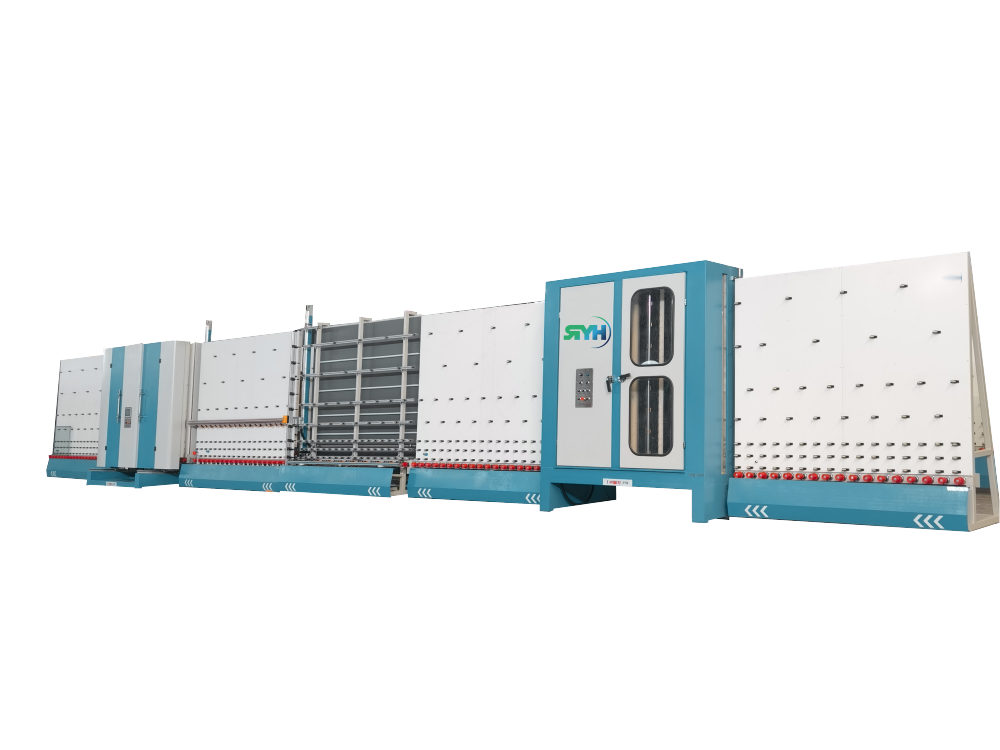

MAIN FEATURES

WASH REGION AND WASH AREAS:

- Constructed with high-quality stainless steel and corrosion-resistant materials to ensure longevity and resistance to harsh cleaning chemicals.

- Equipped with three pairs of independent operation brushes that can be adjusted for brush spacing to accommodate different glass thicknesses.

- Utilizes advanced CNC automation software for precise and consistent operation, ensuring that each glass piece is cleaned to perfection.

1. VERSATILE GLASS PROCESSING CAPABILITIES:

- Capable of producing double glass and triple glass hollow glass, as well as long glass sections.

- The long glass can undergo secondary plate pressing for added strength and stability.

- Offers both automatic and manual operation modes for flexible and straightforward use, making it accessible to operators of varying skill levels.

2. UNIQUE PLATE STRESS ADJUSTMENT TECHNOLOGY:

- Features a proprietary plate stress adjustment technology that allows for fine-tuning of the pressure applied to the glass, ensuring even and gentle handling.

- Includes an automated plate pressure protection function to prevent damage to the glass during the washing process.

3. ADVANCED DRYING SYSTEM:

- Incorporates a circulating warm air drying section that accelerates the cleaning process, ensuring glasses are dry with reduced noise.

- Utilizes high-density soft brushes that are gentle enough to clean all types of LOW-E glasses and coated glasses without scratching.

4. INTELLIGENT DESKTOP CLEANING SYSTEM:

- The desktop is fitted with an advanced smart cleaning system that optimizes the washing process for maximum efficiency and minimal water usage.

5. CUSTOMIZABLE MACHINE OPERATION:

- The direction of the machine's operation can be customized to match the travel direction of the glass, streamlining the production line.

- Offers customizable board inflation feature equipment, including PW-C (external closure inflation) and PW (external closure), to cater to specific processing requirements.

With these features, our glass washing machine is not only a powerful tool for glass manufacturing and processing facilities but also a testament to our commitment to innovation and customer satisfaction.

Voltage | 3P/380V/50Hz | Maximum glass size | 2000×2500mm |

Total power | 28KW | Maximum thickness of insulating glass | 60mm |

Washing speed | 0-13m/min | Air consumption | 1m³/min |

Maximum working speed | 50m/min | Dimension | 18200×2800×2920mm |

Minimum glass size | 300×450mm |