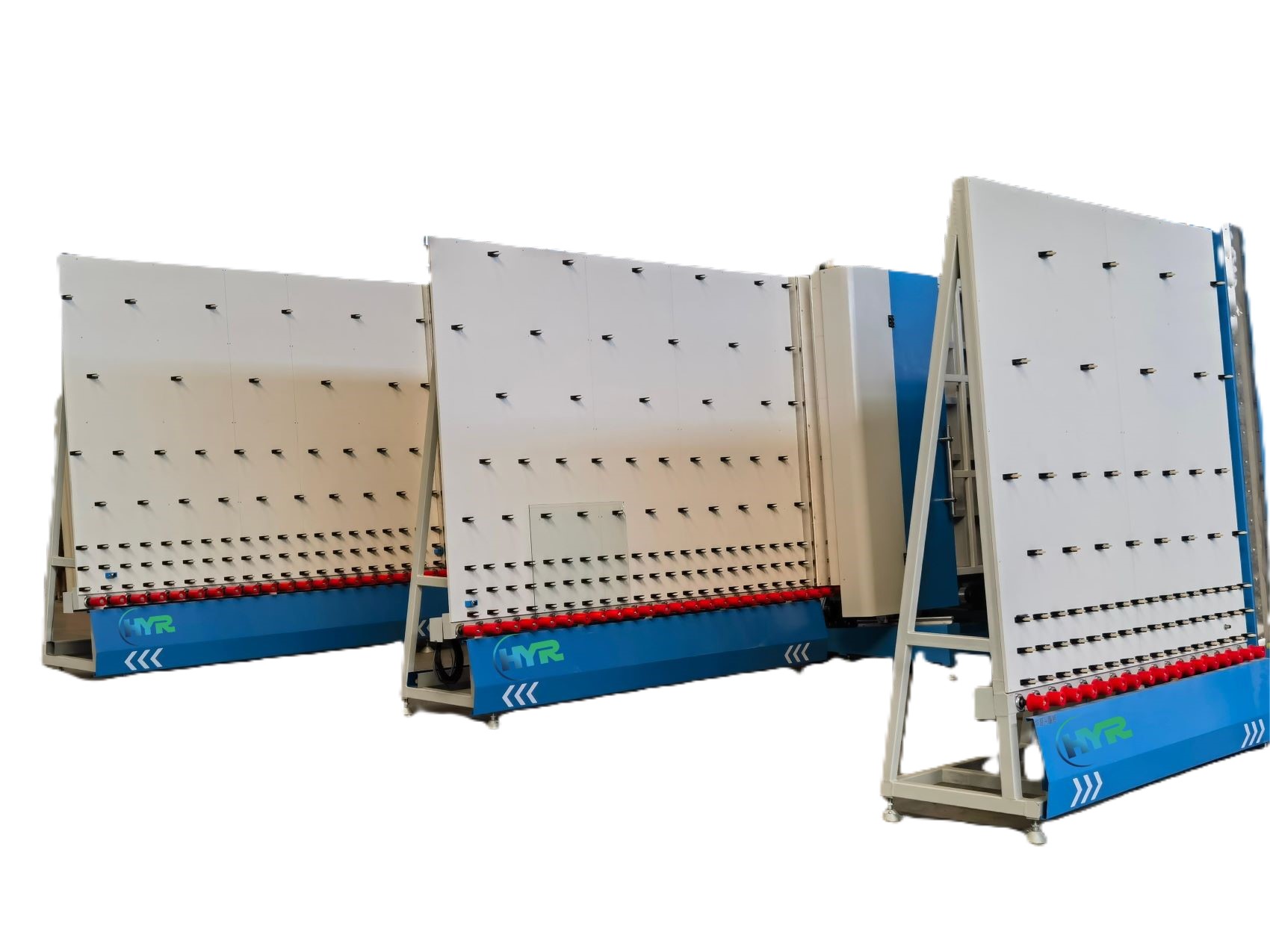

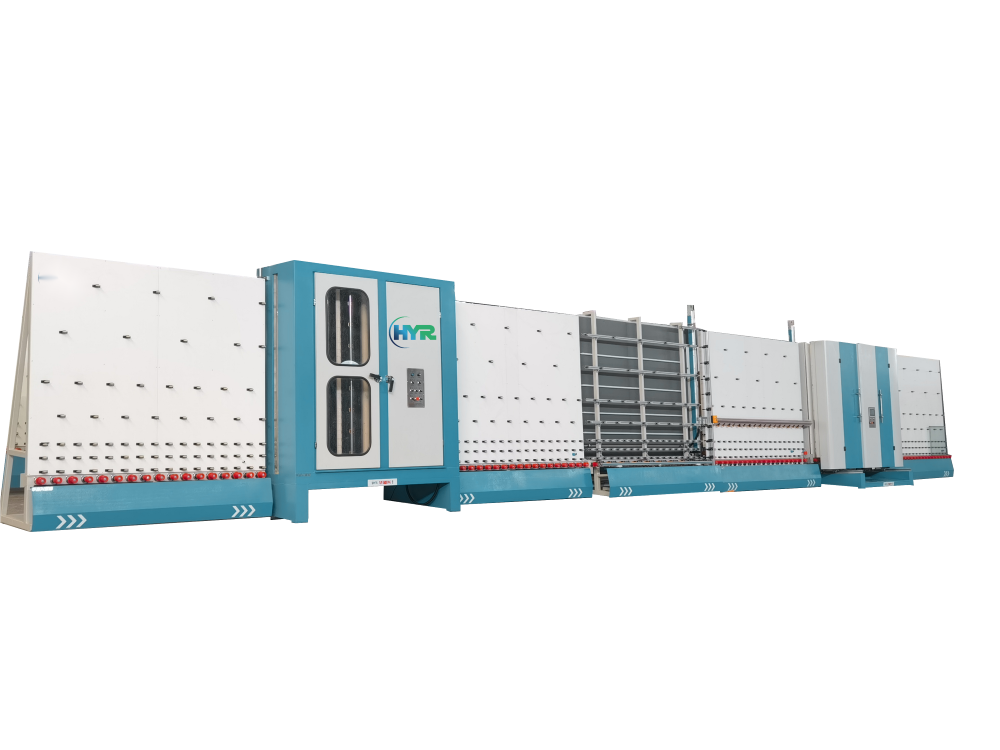

High-Speed Insulating Glass Production Line

MAIN FEATURES

1.Constructed with stainless steel and corrosion-resistant materials, the washing section features three sets of independently operable brushes with adjustable spacing, powered by CNC automated programming;

2.Capable of producing double-glazed and triple-glazed insulating glass, with the ability to repress long glass panels; Offers both automatic and manual operation modes for user convenience;

3.Utilizes a proprietary point adjustment technology for the pressing plate, along with an automatic maintenance function for the pressing mechanism;

4.Equipped with a circulating hot air drying section that enhances cleaning efficiency, ensures thorough drying, and minimizes noise levels; Employs high-density soft brushes suitable for cleaning all types of LOW-E and coated glass;

5.Incorporates an advanced intelligent cleaning system for optimal performance;

6.The machine’s direction of travel can be customized to facilitate either forward or reverse operation, accommodating the glass’s path;

7.The equipment can be tailored to include a board inflation feature, available in PW-C (with external sealed inflation) and PW (with external sealed) configurations.

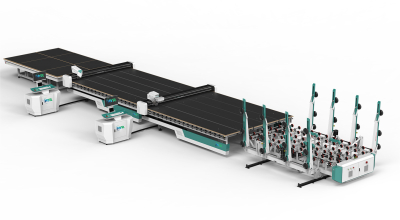

Discover the pinnacle of insulating glass manufacturing with our state-of-the-art Fully Automatic Insulating Glass Production Line. Designed to revolutionize the way you produce double-glazed windows, this system integrates advanced technology with seamless automation to deliver unmatched efficiency, consistency, and quality. Step into the future of glass processing with our innovative solution.

Key Features of the Fully Automatic Insulating Glass Production Line:

1. Comprehensive Automation

- End-to-end automation from loading to unloading, reducing labor costs and increasing production speed.

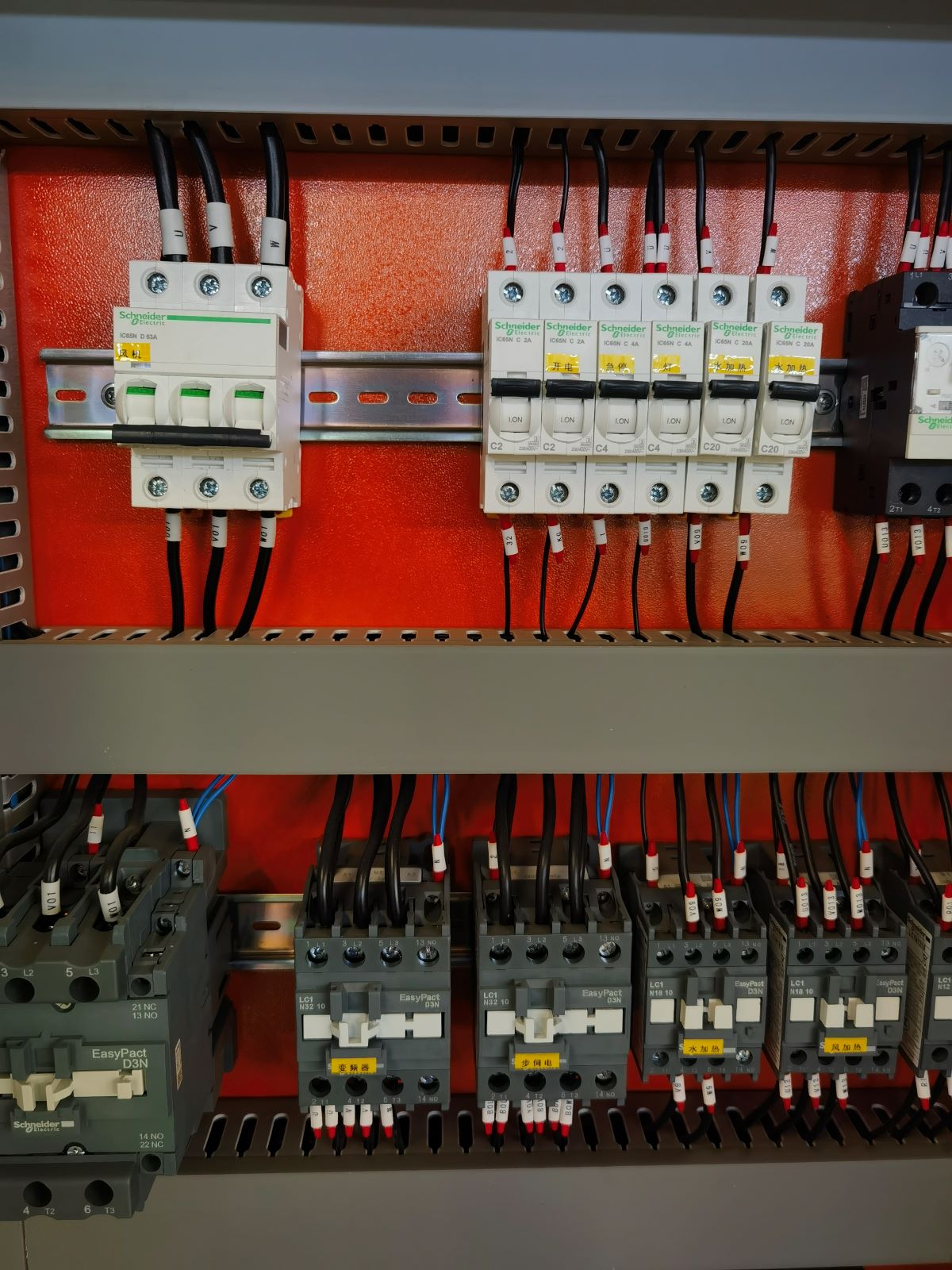

- Intelligent control system for precise operation and minimal human intervention.

2. High-precision Components

- Utilizes high-precision linear guides and ball screws for accurate and stable movement.

- Advanced sealing and spacer insertion mechanisms for perfect alignment and consistency.

3. Versatile and Customizable

- Capable of producing a wide range of insulating glass sizes and shapes to meet various market demands.

- Modular design allows for easy customization and scalability to fit your production needs.

4. Energy Efficiency

- Designed to minimize energy consumption while maintaining high production rates.

- Eco-friendly technology that contributes to a greener production process.

5. Quality Assurance

- Integrated quality control systems ensure each insulating glass unit meets the highest standards.

- Automated inspection processes detect any defects before the final product is packaged.

We have been engaged in the foreign trade industry for many years, and our products are exported to the United States, Kazakhstan, South Korea, Singapore, Thailand, Vietnam, the Philippines, Australia, the United Arab Emirates, South Africa, India and other countries and regions, and enjoy a good reputation all over the world.