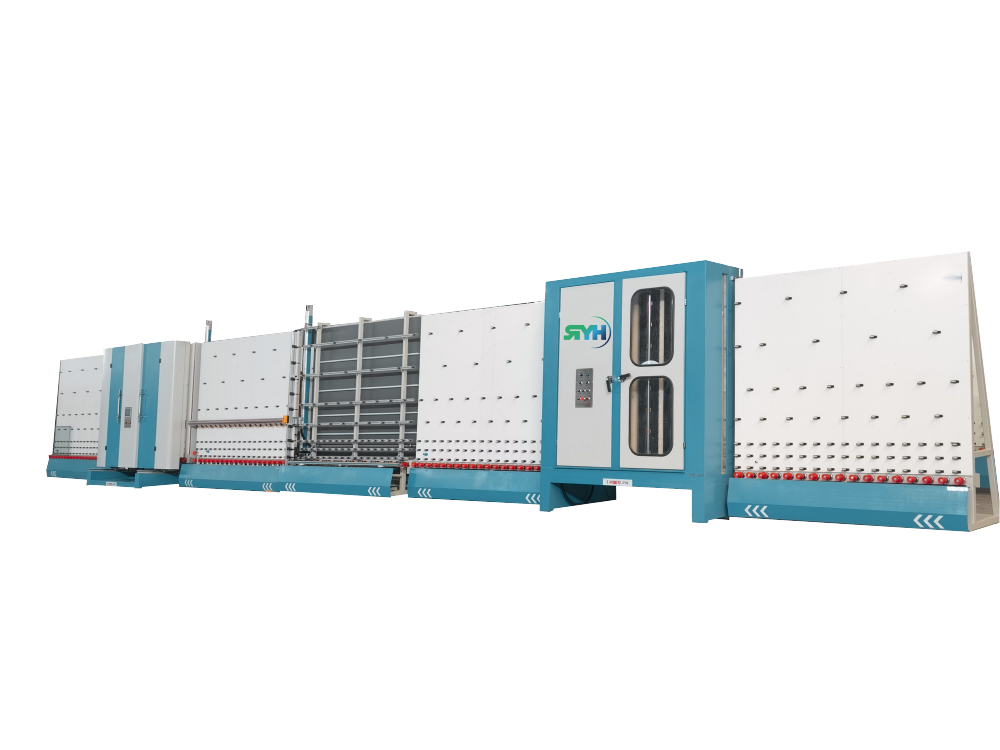

Insulating Glass Production Line Design

Main Features:

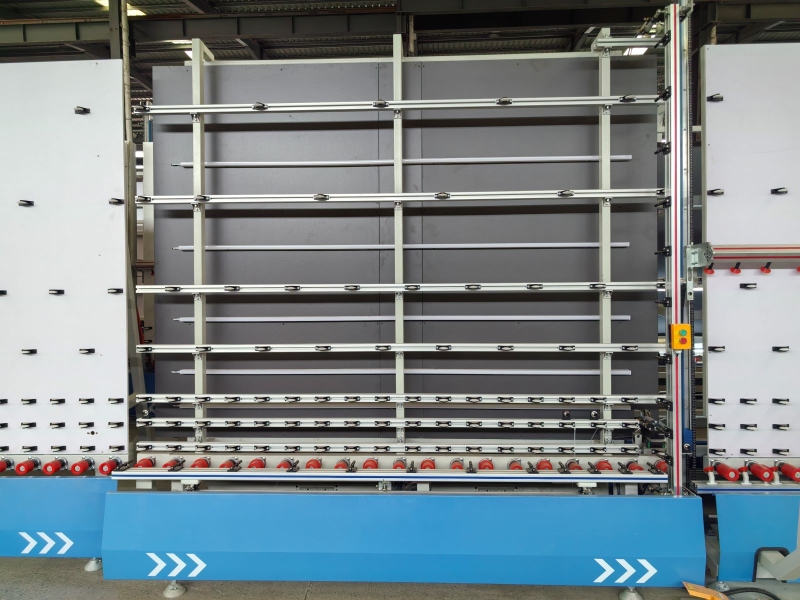

Wash area and wash areas using stainless steel and corrosion-resistant materials, three pairs of independent operation brush, brush spacing is adjustable, using CNC automation program runs;

1. Can produce double glass and three glass hallow glass, long glass, long glass can be secondary plate pressure; Automatic or manual operation, easy to operate;

2. Plate pressure with exclusive point adjustment technology, and with automatic plate presure maintenance function;

3. Circulating hot air drying section, improve the cleaning speed, making it dry reduce noise; All use high-density soft brush, can clean all kind of LOW-E glasses, coated glasses;

4. The machine is equipped with an advanced intelligent cleaning system;

5. Customizable forward and reverse direction of the device according to the direction of travel of the glass.

Customizable in board inflation function equipment, PW-C(external closure inflation), PW(external closure).

Key Features:

1. Stainless Steel and Corrosion-Resistant Construction: The wash area and wash areas are made of stainless steel and corrosion-resistant materials, ensuring durability and resistance to wear.

2. Independent Brush Operation: Equipped with three pairs of independent operation brushes, with adjustable brush spacing for precise cleaning. The machine operates using a CNC automation program for consistent and efficient cleaning.

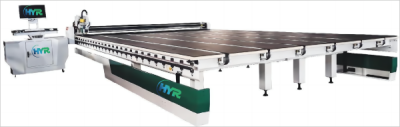

3. Versatile Glass Production: Capable of producing double glass, triple glass hollow glass, and long glass. The long glass can undergo secondary plate pressure, and the machine can be operated automatically or manually for ease of use.

4. Advanced Plate Pressure Technology: Features exclusive point adjustment technology for plate pressure and an automatic plate pressure maintenance function for reliable operation.

5. Efficient Drying System: Equipped with a circulating hot air drying section that improves cleaning speed and reduces noise. The machine uses high-density soft brushes to clean all types of LOW-E glasses and coated glasses.

6. Intelligent Cleaning System: Equipped with an advanced intelligent cleaning system for optimized performance.

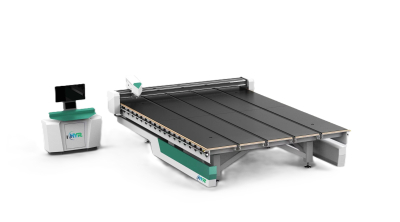

7. Customizable Direction: The device can be customized for forward and reverse direction according to the direction of travel of the glass.

8. Customizable Board Inflation Function: Equipped with customizable board inflation function equipment, including PW-C (external closure inflation) and PW (external closure).

Technical Parameters

Voltage | 3P/380V/50Hz | Maximum glass size | 2000×2500mm |

Total power | 28KW | Maximum thickness of insulating glass | 60mm |

Washing speed | 0-13m/min | Air consumption | 1m³/min |

Maximum working speed | 50m/min | Dimension | 18200×2800×2920mm |

Minimum glass size | 300×450mm |

At present, our products are exported to the United States, Kazakhstan, South Korea, Singapore, Thailand, Vietnam, Philippines, Australia, United Arab Emirates, South Africa, India and other countries and regions, enjoying a worldwide reputation. Looking forward to cooperate with you.