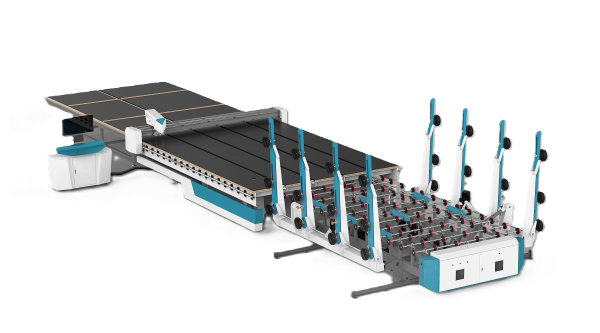

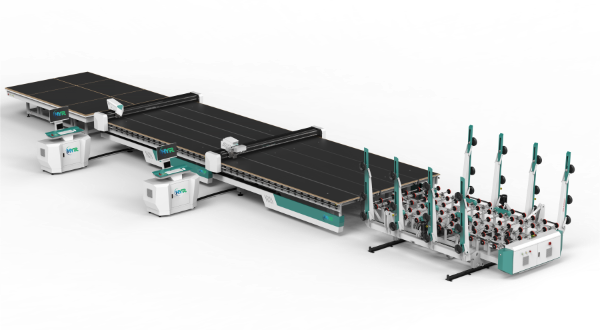

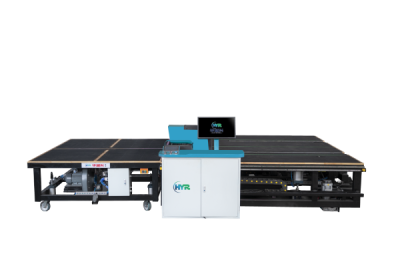

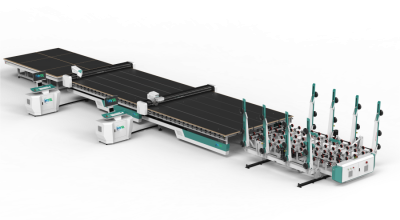

Multi-Functional Glass Cutting and Cleaning System

Product performance

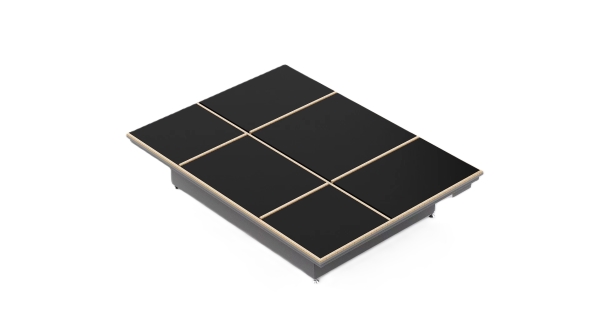

The design draws on the concept of German Industry 4.0, and realizes the automatic cutting process, information data and intelligent operation. The overall frame of the equipment adopts bridge steel technology, which is aged after welding, and the fuselage steel plate is milled out with a gantry mill, which has super strength and stability qualitative. Frame structure material is made of high manganese steel, high strength, no deformation, welding after aging treatment, good physical properties can be matched with bilateral grinding, four-edge grinding line production, glass does not fall, improve work efficiency.

Experience the future of glass cutting with our state-of-the-art Glass Cutting Machine. Engineered to perfection, this cutting-edge technology is designed to enhance productivity, precision, and efficiency in the glass industry. Embrace the power of German Industry 4.0 with our innovative solution that promises to revolutionize your glass processing operations.

Prime Features Redefined:

- Pioneering Automation

- Harness the power of intelligent cutting technology for an error-free process that significantly cuts down on labor costs.

- Enjoy real-time production monitoring and control with our comprehensive data management system.

- Superior Build Integrity

- Constructed using state-of-the-art bridge steel technology for unmatched durability and strength.

- A high manganese steel frame guarantees ruggedness and resistance to deformation under heavy use.

- Enhanced Component Longevity

- Welded joints are subjected to an aging treatment process, enhancing their durability and physical properties for extended use.

- Unrivalled Cutting Accuracy

- Utilizes a gantry mill for exceptionally precise milling of steel plates, ensuring the highest level of cutting accuracy.

- Compatible with both bilateral and four-edge grinding production lines for stable glass handling and accident prevention.

- Versatile Industry Use

- Ideally designed for diverse industries such as construction, automotive, home appliances, and culinaryware.

- Accommodates the processing of various glass materials, from coated glass to mirrors and decorative glass pieces.

- Intuitive User Experience

- Equipped with an easy-to-use control panel that streamlines operations and speeds up configuration.

- Offers customizable cutting patterns and dimensions to meet the specific requirements of different projects.

Technical Details:

Model | ACCURACY | APEED | MAX CUTTING SIZE | THICKNESS | POWER | POWER SUPPLY |

14033 | ≤±0.20mm/m | 0-220m/min | 14000mm×3300mm | 3-19mm | 70kw | 380v/50HZ |

6137 | ≤±0.20mm/m | 0-220m/min | 6100mm×3700mm | 3-19mm | 25kw | 380v/50HZ |

6133 | ≤±0.20mm/m | 0-220m/min | 6100mm×3700mm | 3-19mm | 25kw | 380v/50HZ |

5133 | ≤±0.20mm/m | 0-220m/min | 5100mm×3300mm | 3-19mm | 25kw | 380v/50HZ |

4228 | ≤±0.20mm/m | 0-220m/min | 4200mm×2800mm | 3-19mm | 18kw | 380v/50HZ |

2621 | ≤±0.20mm/m | 0-220m/min | 2600mm×2100mm | 3-19mm | 12kw | 380v/50HZ |

Remark :Special sizes can be customized | ||||||