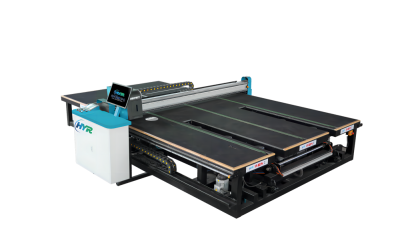

Fast Delivery Glass Cutting Machine

Product Performance Highlights:

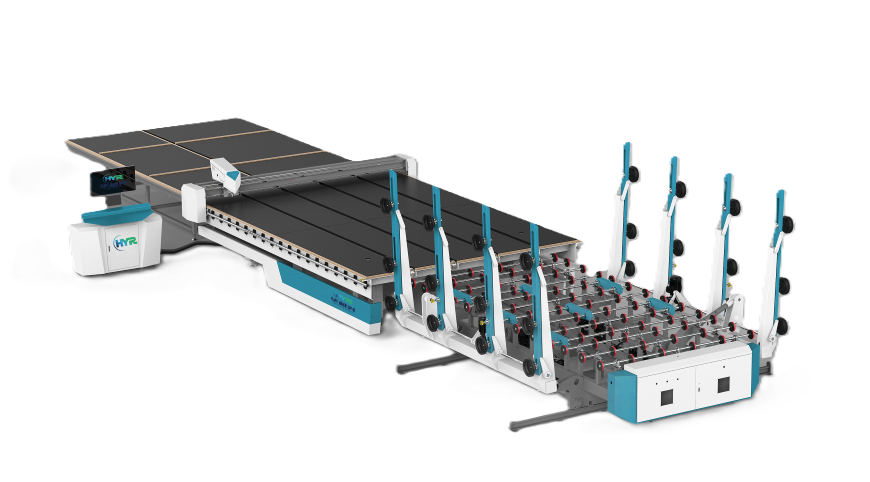

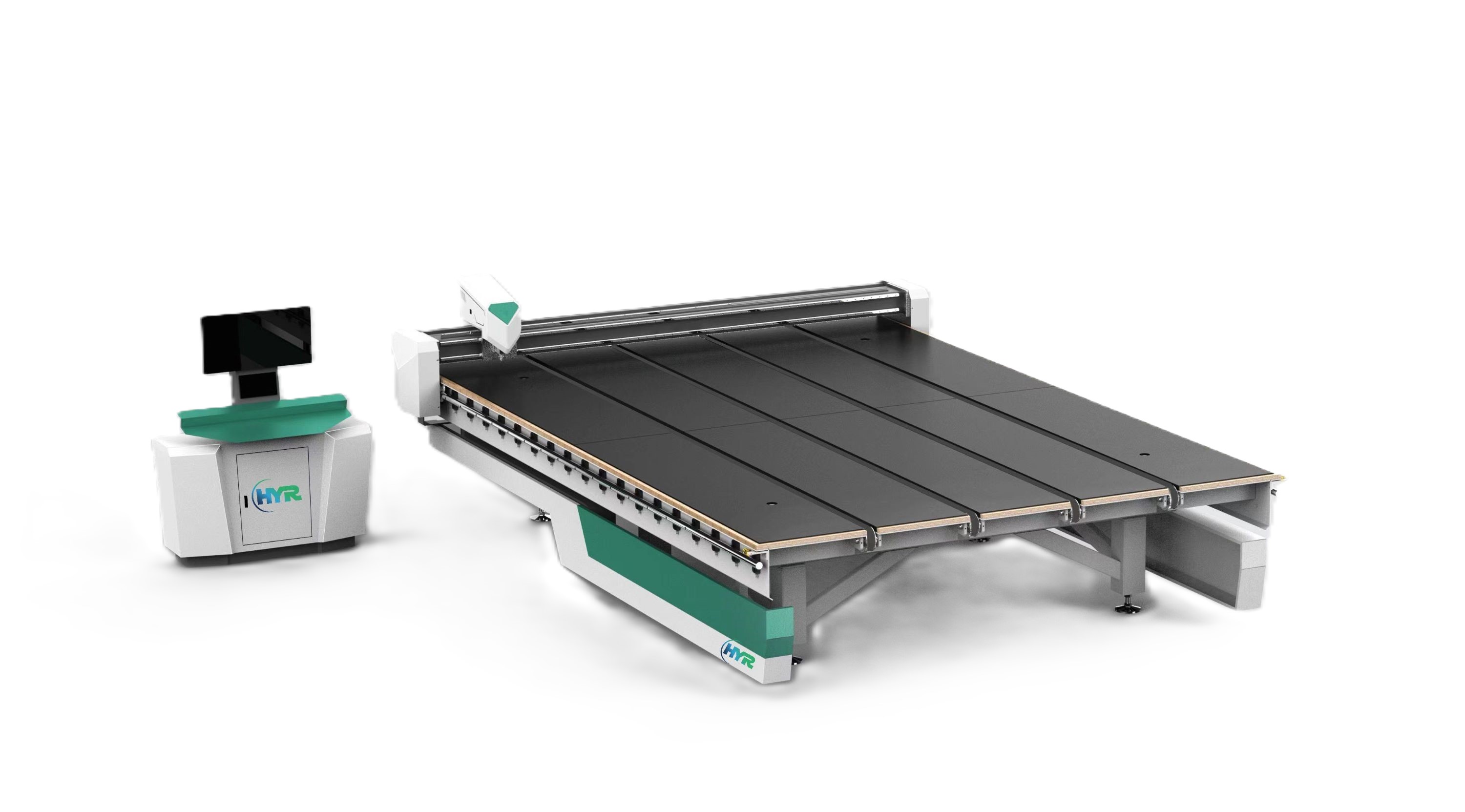

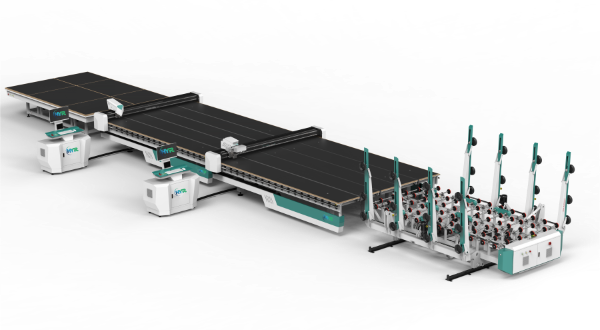

Drawing inspiration from the concept of Germany's Industry 4.0, this machine achieves an automated cutting process, data integration, and intelligent operation. The chassis of the equipment is constructed using bridge steel technology, which undergoes welding and aging processes for enhanced durability. The body metal plate is precision-milled using a gantry mill, ensuring exceptional strength and stability.

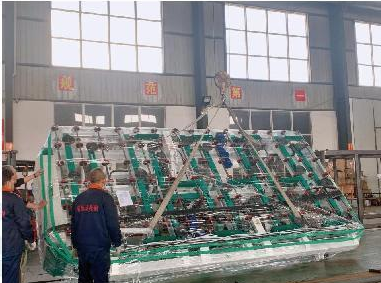

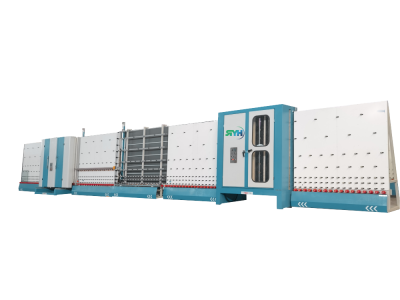

The frame's structural material is crafted from high-manganese steel, renowned for its high tensile strength and resistance to deformation. After welding, it undergoes an aging treatment to refine its physical properties. The frame is designed to accommodate bilateral grinding and a four-edge grinding line, preventing glass from slipping and thereby increasing work efficiency.

Product Performance Excellence:

Leveraging the cutting-edge principles of Germany's vaunted Industry 4.0 initiative, this state-of-the-art machine has been engineered to perform an automated cutting process with precision and ease. It seamlessly integrates data and operates intelligently, streamlining production and enhancing overall efficiency. The robust chassis of the equipment is meticulously constructed with advanced bridge steel technology, ensuring a sturdy foundation that is further fortified by a rigorous welding and aging process to guarantee long-lasting durability.

The body of the machine is crafted from a high-quality metal plate that is meticulously precision-milled by a gantry mill, a process that guarantees exceptional strength and unwavering stability, even under the most demanding operational conditions. The frame itself is an engineering marvel, made from high-manganese steel, a material celebrated for its exceptional tensile strength and its ability to withstand deformation, making it the ideal choice for heavy-duty applications.

Post-welding, the frame undergoes a specialized aging treatment that refines its physical properties, enhancing its structural integrity and ensuring that it remains a reliable workhorse in the most challenging environments. The frame's design is thoughtful and innovative, with the capacity to facilitate bilateral grinding and a unique four-edge grinding line. This feature not only prevents glass from slipping during the production process but also significantly boosts work efficiency, reducing downtime and improving the overall quality of the finished product. The machine's thoughtful design and superior construction set a new standard for performance and reliability in the industry.

Technical Details:

Model | ACCURACY | APEED | MAX CUTTING SIZE | THICKNESS | POWER | POWER SUPPLY |

14033 | ≤±0.20mm/m | 0-220m/min | 14000mm×3300mm | 3-19mm | 70kw | 380v/50HZ |

6137 | ≤±0.20mm/m | 0-220m/min | 6100mm×3700mm | 3-19mm | 25kw | 380v/50HZ |

6133 | ≤±0.20mm/m | 0-220m/min | 6100mm×3700mm | 3-19mm | 25kw | 380v/50HZ |

5133 | ≤±0.20mm/m | 0-220m/min | 5100mm×3300mm | 3-19mm | 25kw | 380v/50HZ |

4228 | ≤±0.20mm/m | 0-220m/min | 4200mm×2800mm | 3-19mm | 18kw | 380v/50HZ |

2621 | ≤±0.20mm/m | 0-220m/min | 2600mm×2100mm | 3-19mm | 12kw | 380v/50HZ |

Remark :Special sizes can be customized | ||||||