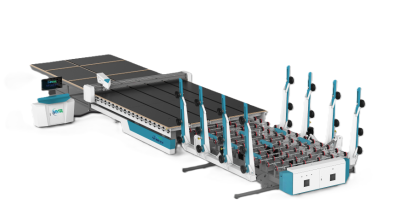

IG Insulating Glass Machine For Sale

Product Advantages:

Advanced Washing Technology:

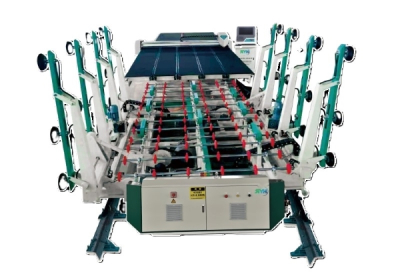

- Crafted from durable stainless steel and corrosion-resistant materials, the washing section boasts three sets of independently controlled brushes with adjustable spacing. These brushes are driven by CNC automated programming, ensuring precision and efficiency in the cleaning process.

Versatile Glass Production:

- Designed for the production of double-glazed and triple-glazed insulating glass, the machine is adept at handling long glass panels. It offers the flexibility of both automatic and manual operation modes, catering to user preferences and varying production needs. The pressing plate employs a unique point adjustment technology, complemented by an automatic maintenance function for the pressing mechanism.

Efficient Drying and Intelligent Cleaning:

- The inclusion of a circulating hot air drying section enhances cleaning efficiency, guarantees thorough drying, and keeps noise levels to a minimum. The machine is equipped with high-density soft brushes ideal for cleaning all types of LOW-E and coated glass. An advanced intelligent cleaning system is integrated to ensure peak performance. Additionally, the machine's travel direction is customizable, allowing for either forward or reverse operation to suit the glass's path. Customization options include a board inflation feature, available in PW-C and PW configurations, further enhancing the machine's versatility.

Product Details

Advanced Washing Technology: Crafted from durable stainless steel and corrosion-resistant materials, the washing section boasts three sets of independently controlled brushes with adjustable spacing. These brushes are pushed by using CNC automatic programming, making sure precision and effectivity in the cleansing process.

Versatile Glass Production: Designed for the production of double-glazed and triple-glazed insulating glass, the machine is adept at handling long glass panels. It provides the flexibility of each computerized and guide operation modes, catering to consumer preferences and various manufacturing needs. The urgent plate employs a special factor adjustment technology, complemented via an computerized upkeep feature for the urgent mechanism.

Efficient Drying and Intelligent Cleaning: The inclusion of a circulating hot air drying section enhances cleaning efficiency, guarantees thorough drying, and keeps noise levels to a minimum. The laptop is geared up with high-density gentle brushes perfect for cleansing all sorts of LOW-E and covered glass. An superior shrewd cleansing device is built-in to make sure height performance. Additionally, the machine's tour path is customizable, permitting for both ahead or reverse operation to go well with the glass's path. Customization selections encompass a board inflation feature, handy in PW-C and PW configurations, similarly improving the machine's versatility.

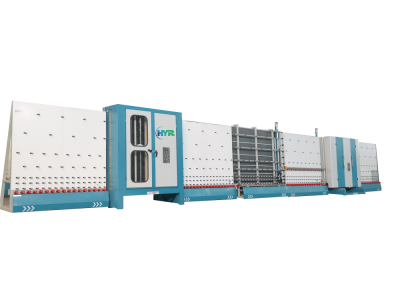

Technical Characteristics:

Voltage | 3P/380V/50Hz | Maximum glass size | 2000×2500mm |

Total power | 28KW | Maximum thickness of insulating glass | 60mm |

Washing speed | 0-13m/min | Air consumption | 1m³/min |

Maximum working speed | 50m/min | Dimension | 18200×2800×2920mm |

Minimum glass size | 300×450mm |