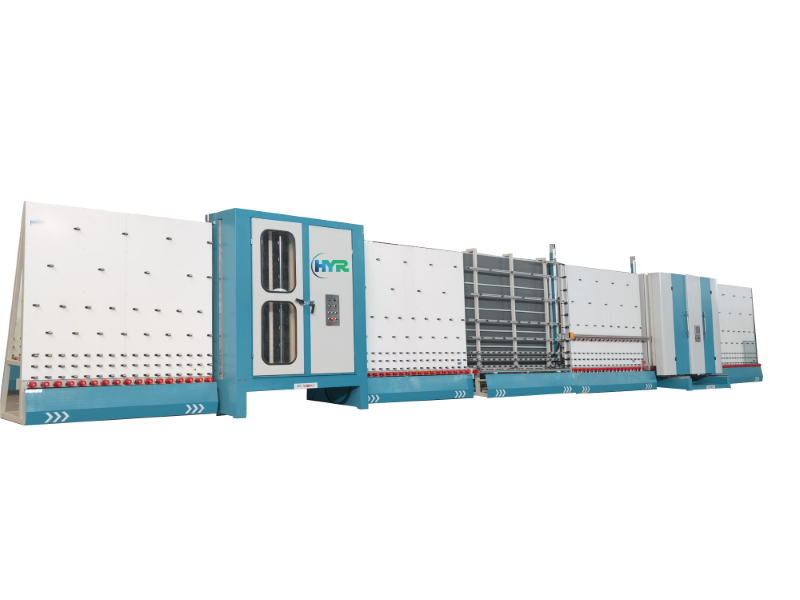

Panel Inflatable Insulating Glass Production Line

MAIN FEATURES

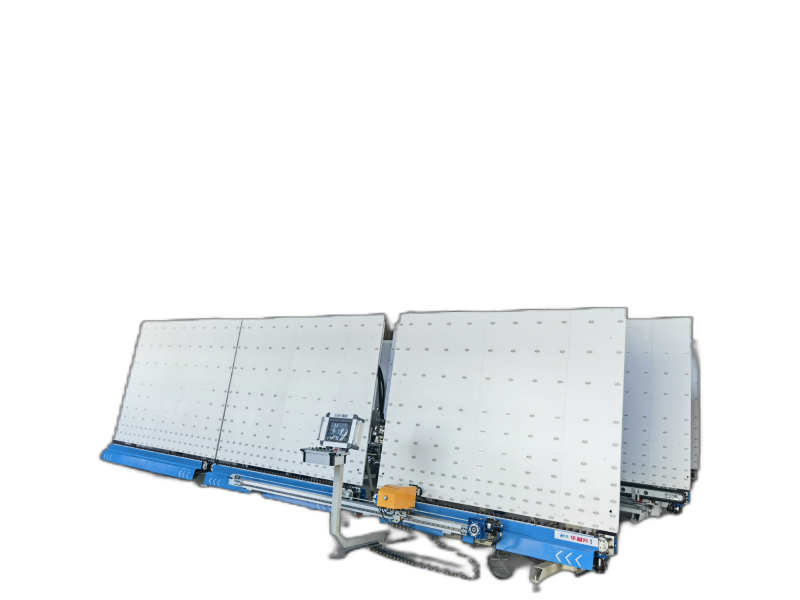

Wash area and wash areas using stainless steel and corrosion-resistant materials, three pairs of independent operation brush, brush spacing is adjustable, using CNC automation program runs;

1.Can produce double glass and three glass hallow glass, long glass, long glass can be secondary plate pressure; Automatic or manual operation, easy to operate;

2.Plate pressure with exclusive point adjustment technology, and with automatic plate presure maintenance function;

3.Circulating hot air drying section, improve the cleaning speed, making it dry reduce noise; All use high-density soft brush, can clean all kind of LOW-E glasses, coated glasses;

4.The machine is equipped with an advanced intelligent cleaning system;

5.Customizable forward and reverse direction of the device according to the direction of travel of the glass.

Customizable in board inflation function equipment, PW-C(external closure inflation), PW(external closure).

Product Characteristics:

- Streamlined Material Handling: The innovative system autonomously handles the loading of glass sheets and the unloading of completed insulating glass units, minimizing manual intervention and the risk of damage.

- Superior Butyl Extrusion: Equipped with a top-tier butyl extruder that guarantees impermeable and resilient seals, enhancing insulation efficiency.

- Accurate Spacer Bar Placement: Mechanized precision for the insertion of spacer bars, maintaining uniform spacing and facilitating gas filling processes.

- Automated Gas Inflation: Features a state-of-the-art gas filling station for the injection of argon or other inert gases, which optimizes thermal insulation capabilities.

- Advanced Sealing Techniques: Implements cutting-edge sealing technology for both primary and secondary seals to ensure enduring insulation characteristics.

- Integrated Curing Facility: Includes a curing oven that facilitates fast and even curing of sealing materials for a perfect finish.

- Quality Assurance and Packaging: Robust automated inspection followed by secure and optimized packaging procedures for safe and efficient transportation.

Product Advantages:

- Elevated Production Volume: Capable of producing up to [specified production rate] insulating glass units hourly.

- Labor Cost Optimization: Significantly reduces the dependency on skilled labor due to the comprehensive automation of the process.

- Uniform Quality Assurance: Delivers units that consistently meet stringent quality benchmarks with precision and reliability.

- Improved Energy Conservation: Manufactures insulating glass that adheres to contemporary building standards for energy efficiency.

- Minimal Maintenance Requirements: Engineered for long-lasting performance with ease of maintenance to ensure uninterrupted production flow.

Technical Parameters

Voltage | 3P/380V/50Hz | Maximum glass size | 2000×2500mm |

Total power | 28KW | Maximum thickness of insulating glass | 60mm |

Washing speed | 0-13m/min | Air consumption | 1m³/min |

Maximum working speed | 50m/min | Dimension | 18200×2800×2920mm |

Minimum glass size | 300×450mm |