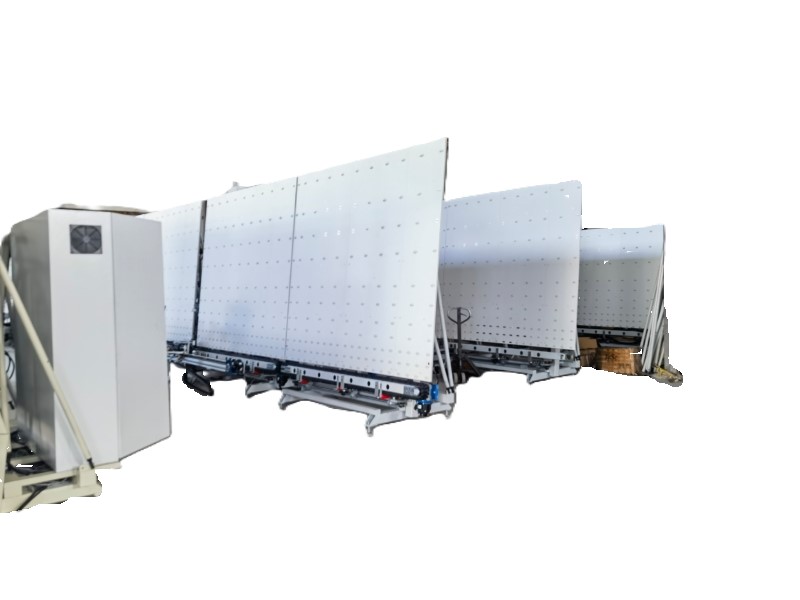

Industrial-Grade Double Glazed Sealed Unit Productor

Product Features:

- Automated Loading and Unloading: The system automatically loads glass sheets and unloads finished insulating glass units, reducing manual handling and potential damage.

- Butyl Extrusion: High-performance butyl extruder ensures airtight and durable seals for improved insulation.

- Spacer Bar Insertion: Precise insertion of spacer bars for consistent spacing and gas filling.

- Gas Filling: Automated gas filling station for argon or other inert gases to enhance thermal performance.

- Sealing: Advanced sealing technology for both primary and secondary seals, ensuring long-lasting insulation properties.

- Curing Oven: Integrated curing oven for rapid and uniform sealing material curing.

- Inspection and Packaging: Automated inspection followed by secure and efficient packaging for transport.

Benefits:

- Increased Production Capacity: Achieve up to [specified production rate] insulating glass units per hour.

- Reduced Labor Costs: Minimize the need for skilled labor with a fully automated process.

- Consistent Quality: Ensure every unit meets the highest quality standards with repeatable precision.

- Enhanced Energy Efficiency: Produce energy-efficient insulating glass that meets modern building codes.

- Low Maintenance: Designed for durability and ease of maintenance to keep your production line running smoothly.

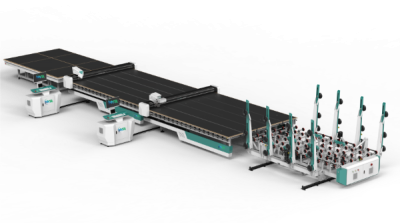

Detailed Product Features:

- Automated Loading and Unloading: The system automatically loads glass sheets and unloads finished insulating glass units, reducing manual handling and potential damage.

- Butyl Extrusion: High-performance butyl extruder ensures airtight and durable seals for improved insulation.

- Spacer Bar Insertion: Precise insertion of spacer bars for consistent spacing and gas filling.

- Gas Filling: Automated gas filling station for argon or other inert gases to enhance thermal performance.

- Sealing: Advanced sealing technology for both primary and secondary seals, ensuring long-lasting insulation properties.

- Curing Oven: Integrated curing oven for rapid and uniform sealing material curing.

- Inspection and Packaging: Automated inspection followed by secure and efficient packaging for transport.

Benefits:

- Increased Production Capacity: Achieve up to [specified production rate] insulating glass units per hour.

- Reduced Labor Costs: Minimize the need for skilled labor with a fully automated process.

- Consistent Quality: Ensure every unit meets the highest quality standards with repeatable precision.

- Enhanced Energy Efficiency: Produce energy-efficient insulating glass that meets modern building codes.

- Low Maintenance: Designed for durability and ease of maintenance to keep your production line running smoothly.

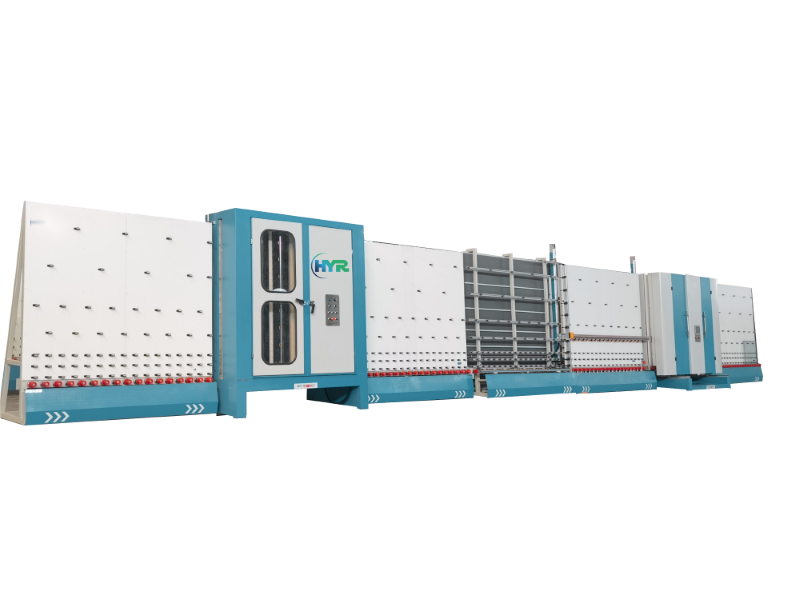

MAIN FEATURES

Wash area and wash areas using stainless steel and corrosion-resistant materials, three pairs of independent operation brush, brush spacing is adjustable, using CNC automation program runs;

1.Can produce double glass and three glass hallow glass, long glass, long glass can be secondary plate pressure; Automatic or manual operation, easy to operate;

2.Plate pressure with exclusive point adjustment technology, and with automatic plate presure maintenance function;

3.Circulating hot air drying section, improve the cleaning speed, making it dry reduce noise; All use high-density soft brush, can clean all kind of LOW-E glasses, coated glasses;

4.The machine is equipped with an advanced intelligent cleaning system;

5.Customizable forward and reverse direction of the device according to the direction of travel of the glass.

Customizable in board inflation function equipment, PW-C(external closure inflation), PW(external closure).

Technical Specifications:

Voltage | 3P/380V/50Hz | Maximum glass size | 2000×2500mm |

Total power | 28KW | Maximum thickness of insulating glass | 60mm |

Washing speed | 0-13m/min | Air consumption | 1m³/min |

Maximum working speed | 50m/min | Dimension | 18200×2800×2920mm |

Minimum glass size | 300×450mm |