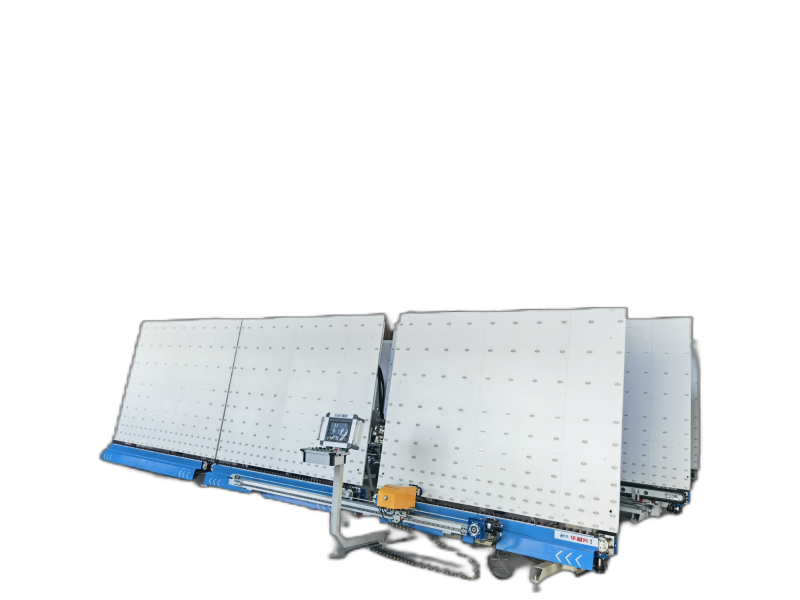

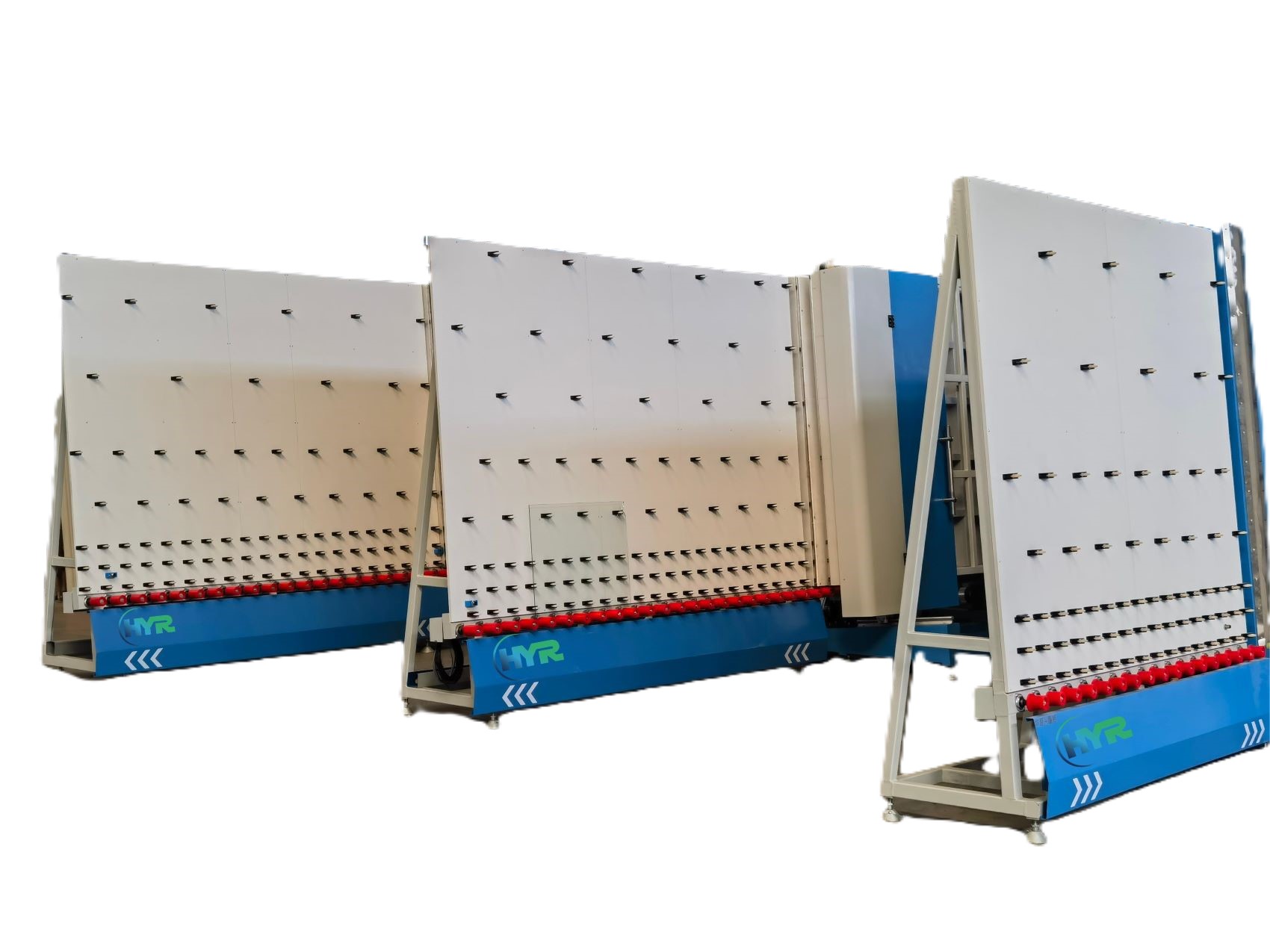

Fully Automatic Glass Sealer Vacuum Machine

Primary Features:

1. Versatile Insulating Glass Gluing: Capable of gluing a variety of sizes of rectangular insulating glass, ensuring high glue efficiency and stable quality. The machine is composed of four sections, with the first section capable of pre-storing a piece of glass and the fourth section for film waiting, offering an efficiency 20% higher than other manufacturers.

2. Convenient Operation: Equipped with a button switch design for common functions, making operation simpler and more convenient for training employees. Detailed parameters can be adjusted using a touch film screen.

3. Precision Gluing: Ensures bubble-free glue application on the sides, full coverage at the corners, and no need for manual trimming.

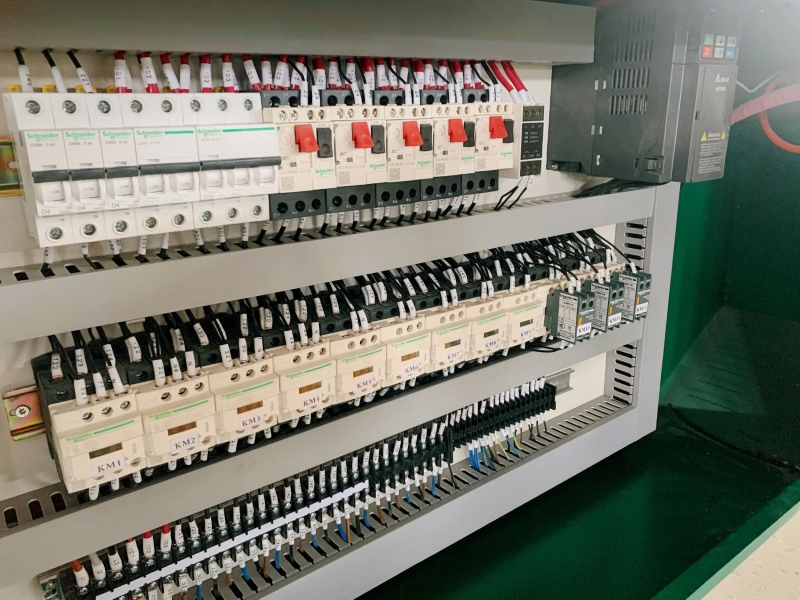

4. Reliable Control System: Equipped with a world-renowned brand servo control system for stable performance.

5. Smooth Glass Movement: Incorporates an accurate synchronous belt transmission system to ensure the smooth running of glass without adhesive.

6. Advanced Glue Management: Features a unique glue amount automatic alarm device and an automatic glue discharge function for efficient operation.

7. Customizability: Can be customized according to customer requirements, including reverse operation and various equipment sizes.

8. Durable Construction: The inlet and outlet are made of an all-aluminum structure, providing waterproofing and enhanced durability.

Key Features:

1. Adaptable Gluing for Various Sizes: The machine is designed to efficiently glue insulating glass of various rectangular sizes, ensuring high glue application efficiency and consistent quality. It is divided into four sections, with the first section for glass pre-storage and the fourth section for film waiting, offering a 20% higher efficiency compared to other manufacturers.

2. User-Friendly Operation: Equipped with a simple button switch design for common functions, making operation easy and convenient for training new employees. Detailed parameters can be easily adjusted using a touch film screen.

3. Precision Gluing Process: The machine ensures bubble-free glue application on the sides, full coverage at the corners, and eliminates the need for manual trimming.

4. Robust Control System: Equipped with a servo control system from a renowned brand, providing stable and reliable performance.

5. Seamless Glass Handling: Incorporates an accurate synchronous belt transmission system to ensure smooth and adhesive-free movement of glass.

6. Efficient Glue Management: Features a unique automatic alarm device for glue level monitoring and an automatic glue discharge function.

7. Customization: Can be customized according to customer requirements, including reverse operation and various equipment sizes.

8. Durable Design: The inlet and outlet are constructed from an all-aluminum structure, offering waterproofing and enhanced durability.

TECHNICAL PARAMETERS

Voltage | 3P/380V/50Hz | Insulating glass thickness | 12-60mm |

Total power | 14KW | Coating depth | 3-15mm |

Transfer speed | 0-50m/min | Aluminum frame width | 6-27mm |

Min.glass. size | 300×180mm | Coating rate | 5-40m/min

|

Max.Glass. Size | 4000×2500mm | Hydraulic pressure | <100kg/cm² |

Overall dimension | 11250×2500×3350mm | Air source | 0.6-0.8MPa |

At present, our products are exported to the United States, Kazakhstan, South Korea, Singapore, Thailand, Vietnam, Philippines, Australia, United Arab Emirates, South Africa, India and other countries and regions, enjoying a worldwide reputation.