Low-energy Sealing Machine For Insulting Glass

Key Features:

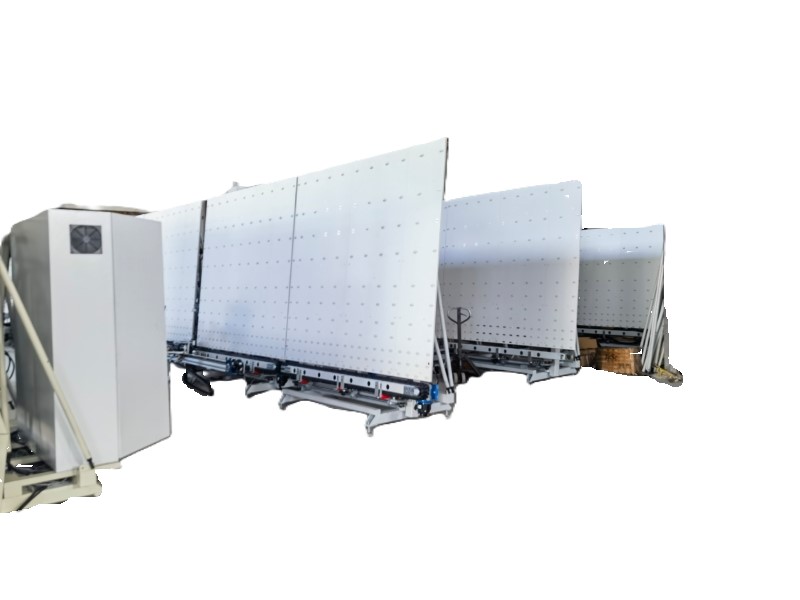

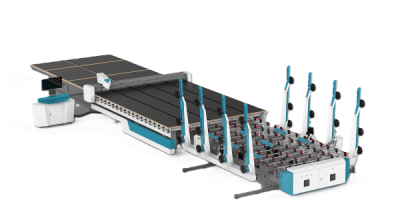

1. Versatile Gluing Capabilities: Capable of continuous glue application for various rectangular insulating glass sizes, ensuring high efficiency and consistent quality. The machine's four sections include a pre-storage area for glass and a film waiting section, enhancing efficiency by 20% over competitors.

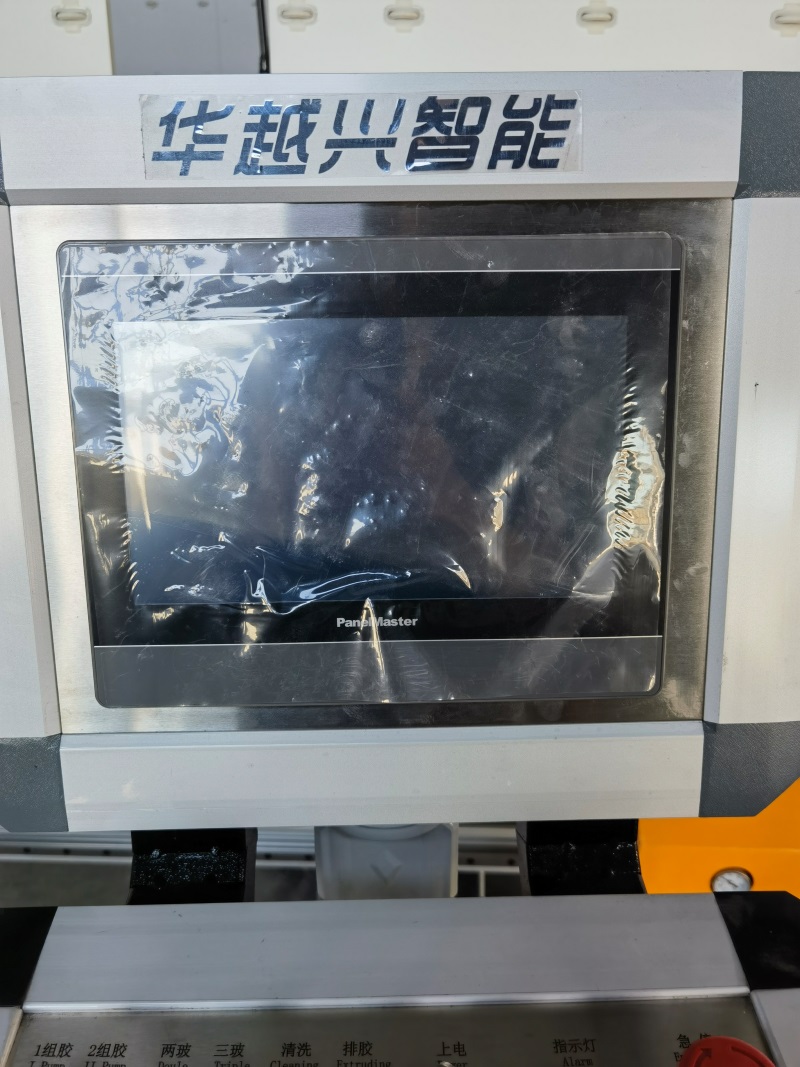

2. User-Friendly Operation: Features a button switch design for common functions, streamlining operation and training. Detailed parameters are adjustable via a touch film screen interface.

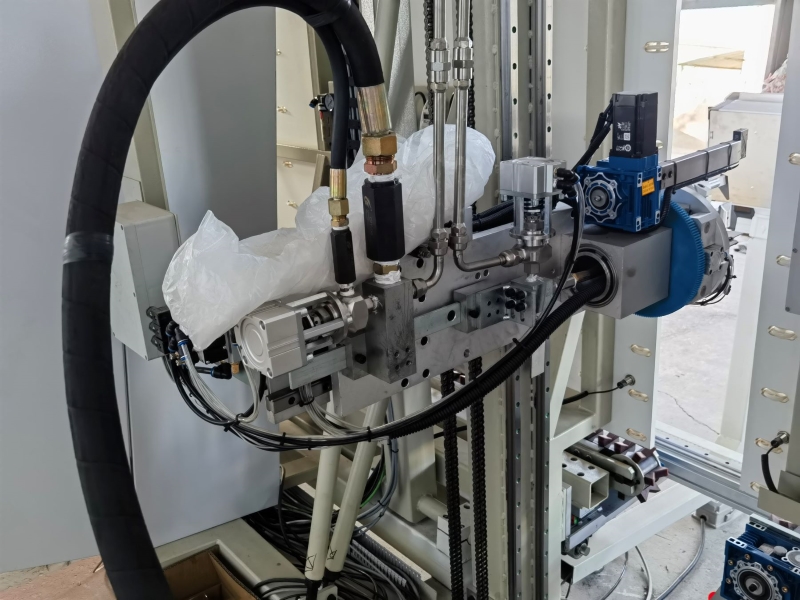

3. Precision Gluing: Ensures bubble-free glue application on sides and full corners, without the need for manual trimming.

4. Reliable Control System: Equipped with a servo control system from a world-renowned brand, ensuring stable performance.

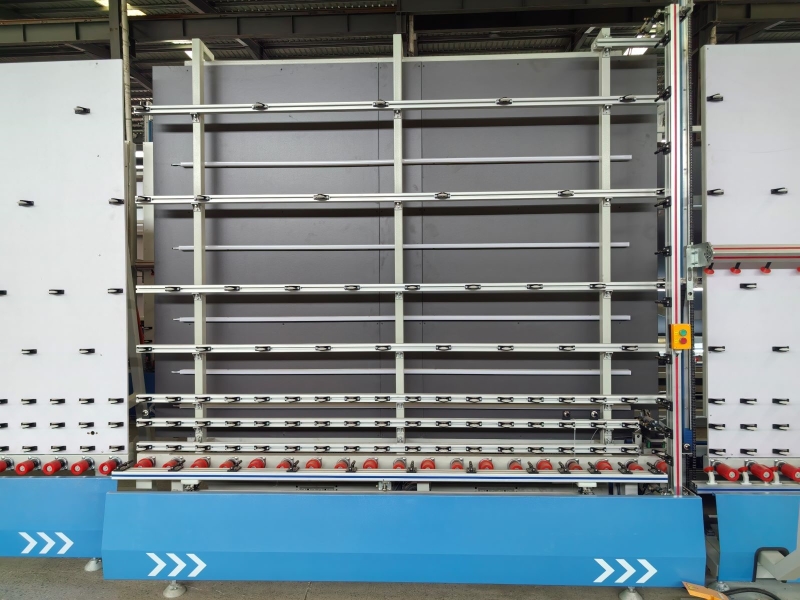

5. Smooth Glass Handling: An accurate synchronous belt transmission system guarantees adhesive-free glass movement.

6. Advanced Glue Management: Includes an automatic alarm for glue levels and an automatic discharge function for efficient operation.

7. Customization Options: Machine can be customized to customer specifications, including reverse operation and various equipment sizes.

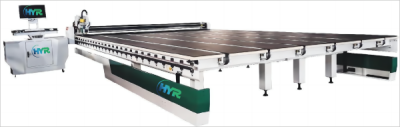

8. Durable Construction: Inlet and outlet sections are built with an all-aluminum structure, providing waterproofing and enhanced durability.

Distinctive Attributes:

1. Adaptable Gluing Functionality: The machine is designed to apply glue continuously and efficiently to insulating glass of various rectangular dimensions, maintaining a high standard of quality. Comprising four distinct sections, it includes a dedicated area for pre-storing glass and a section for film application, which collectively improve the machine's efficiency by an impressive 20% compared to similar machines on the market.

2. Simplified and Intuitive Operation: The equipment is equipped with a button switch design for frequently used functions, making it exceptionally easy to operate and simplifying the training process for new employees. Additionally, the touch film screen interface allows for fine-tuning of operational parameters with precision and ease.

3. Exact Gluing Precision: The machine is engineered to apply glue to the sides and corners of the glass with absolute precision, ensuring a bubble-free finish and complete coverage without the need for any manual trimming, which saves time and labor.

4. Dependable Control Mechanism: Outfitted with a servo control system from a globally acclaimed brand, this machine promises stable and reliable performance, reducing the risk of operational downtime.

5. Seamless Glass Transport: The machine incorporates an accurate synchronous belt transmission system that ensures the glass moves through the machine without any adhesive contact, maintaining the integrity and quality of the glass.

6. Sophisticated Glue Management: An innovative feature of this machine is its automatic alarm system for monitoring glue levels and an automatic glue discharge function, which enhance the overall efficiency and reliability of the gluing process.

7. Customization Flexibility: The machine offers a high degree of customization to meet specific customer needs, including the option for reverse operation and the ability to accommodate various equipment sizes to suit different production requirements.

8. Robust and Water-Resistant Build: The inlet and outlet sections of the machine are constructed from an all-aluminum frame, which not only provides exceptional durability but also ensures waterproofing, making the machine suitable for a variety of environmental conditions and extending its lifespan.

Technical Parameters

Voltage | 3P/380V/50Hz | Insulating glass thickness | 12-60mm |

Total power | 14KW | Coating depth | 3-15mm |

Transfer speed | 0-50m/min | Aluminum frame width | 6-27mm |

Min.glass. size | 300×180mm | Coating rate | 5-40m/min

|

Max.Glsss. Size | 4000×2500mm | Hydraulic pressure | <100kg/cm² |

Overall dimension | 11250×2500×3350mm | Air source | 0.6-0.8MPa |

At present, our products are exported to the United States, Kazakhstan, South Korea, Singapore, Thailand, Vietnam, Philippines, Australia, United Arab Emirates, South Africa, India and other countries and regions, enjoying a worldwide reputation.