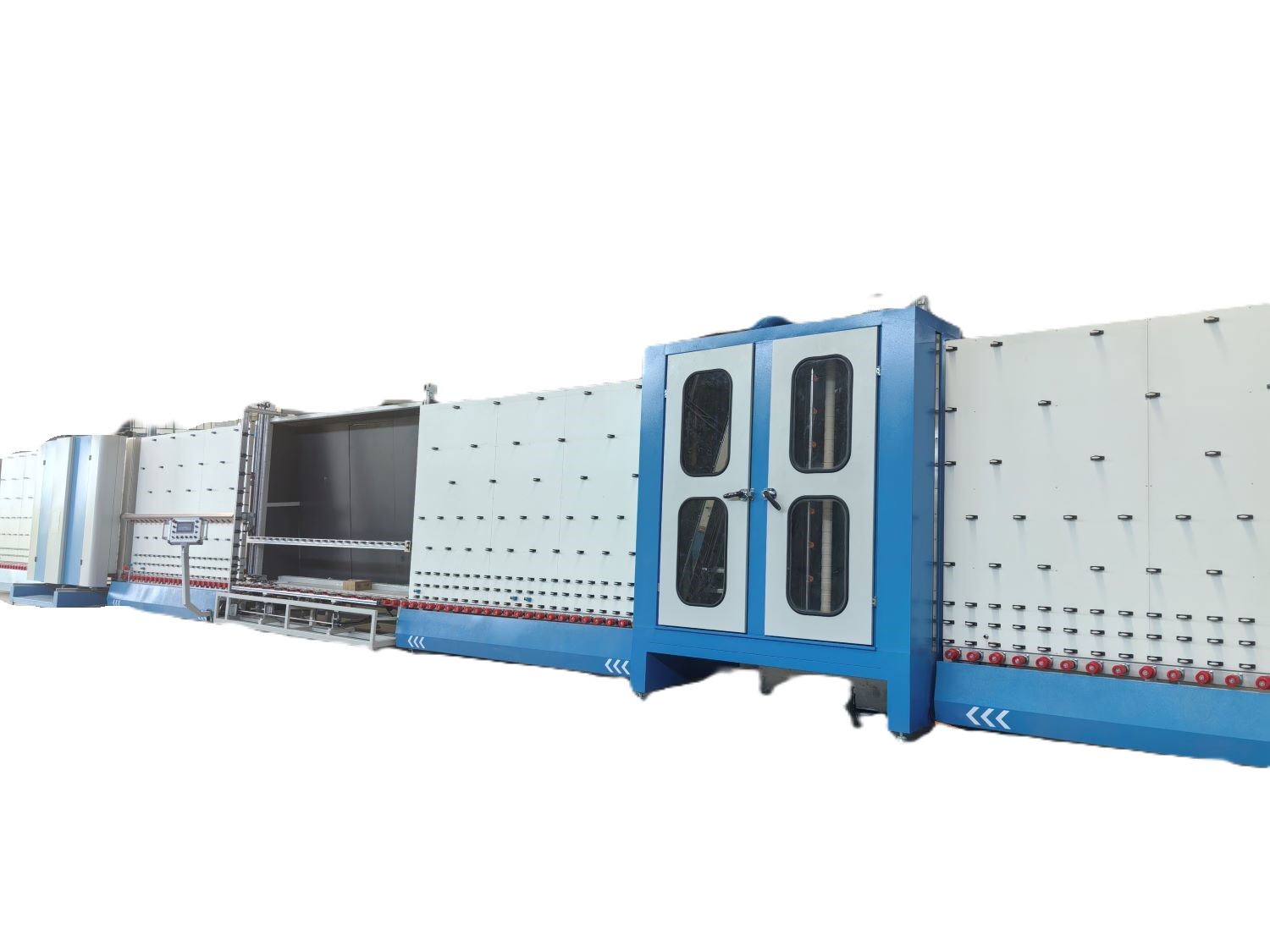

Double Glass Manufacturing Line

**Advanced Insulating Glass Production Line with High-Tech Washing and Drying Features:**

- This state-of-the-art production line is made of robust stainless steel and features corrosion-resistant components. It is equipped with three sets of independently controlled brushes, adjustable for precision cleaning. The brushing process is automated by CNC programming for optimal efficiency.

- The line is versatile, capable of producing double and triple-glazed insulating glass, and can handle extended glass panels. It offers both automatic and manual operation modes to accommodate different production requirements. A unique point adjustment technology is used for the pressing plate, along with an automatic maintenance function for the pressing mechanism.

- The line includes a hot air drying section that circulates hot air for efficient cleaning and drying, while maintaining low noise levels. It is fitted with high-density soft brushes suitable for cleaning various types of glass, including LOW-E and coated glass. An intelligent cleaning system is integrated to ensure the machine operates at its best. The travel direction of the machine is customizable for forward or reverse operation, and it offers optional board inflation features in PW-C and PW configurations, adding to its adaptability.

Product Details

**Advanced Washing Technology:**

- Crafted from durable stainless steel and corrosion-resistant materials, the washing section boasts three sets of independently controlled brushes with adjustable spacing. These brushes are driven by CNC automated programming, ensuring precision and efficiency in the cleaning process.

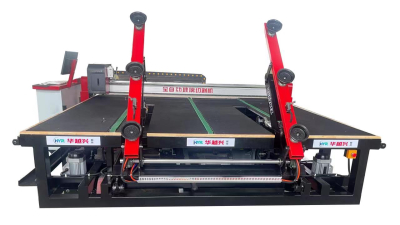

**Versatile Glass Production:**

- Designed for the production of double-glazed and triple-glazed insulating glass, the machine is adept at handling long glass panels. It offers the flexibility of both automatic and manual operation modes, catering to user preferences and varying production needs. The pressing plate employs a unique point adjustment technology, complemented by an automatic maintenance function for the pressing mechanism.

**Efficient Drying and Intelligent Cleaning:**

- The inclusion of a circulating hot air drying section enhances cleaning efficiency, guarantees thorough drying, and keeps noise levels to a minimum. The machine is equipped with high-density soft brushes ideal for cleaning all types of LOW-E and coated glass. An advanced intelligent cleaning system is integrated to ensure peak performance. Additionally, the machine's travel direction is customizable, allowing for either forward or reverse operation to suit the glass's path. Customization options include a board inflation feature, available in PW-C and PW configurations, further enhancing the machine's versatility.

Technical Parameters

Voltage | 3P/380V/50Hz | Maximum glass size | 2000×2500mm |

Total power | 28KW | Maximum thickness of insulating glass | 60mm |

Washing speed | 0-13m/min | Air consumption | 1m³/min |

Maximum working speed | 50m/min | Dimension | 18200×2800×2920mm |

Minimum glass size | 300×450mm |