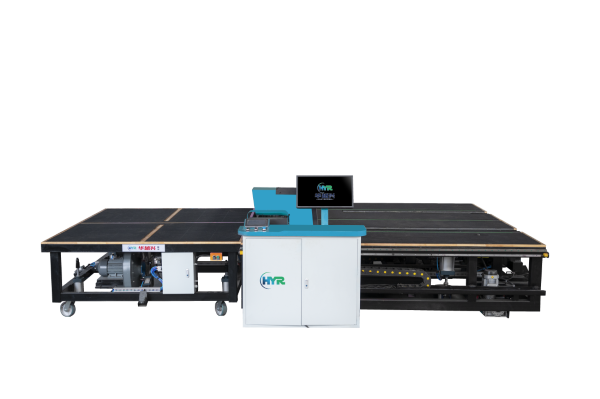

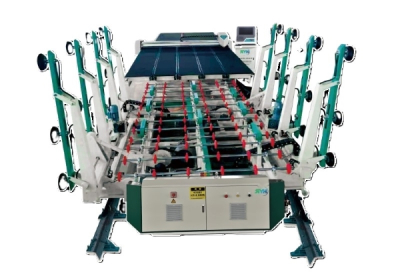

Leading Technology Glass Cutting Table

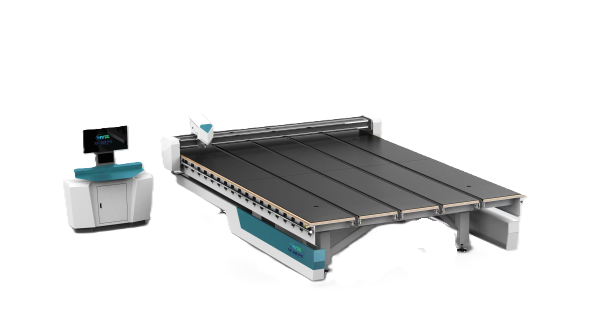

A glass cutting table is a specialized equipment used for cutting and processing glass, designed to enhance cutting accuracy and efficiency while ensuring operational safety. Here are some features of a glass cutting table:

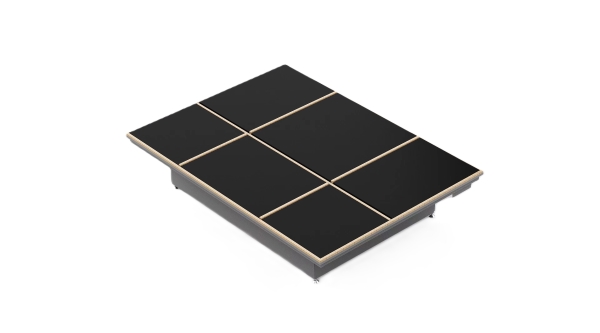

1. Stable Work Surface: The table surface is made of materials with high flatness to ensure the glass remains stable during cutting, preventing cutting deviations caused by vibrations.

2. Precise Cutting Guidance: Equipped with precise cutting rulers and guiding systems, it facilitates the operator's precise marking and cutting.

3. Safety Protection: The table is surrounded by safety protection devices, such as guards or emergency stop buttons, to protect the safety of the operator.

4. Adjustable Height: The height of the table is adjustable to accommodate the height requirements of different operators, reducing fatigue from long hours of work.

5. Durability: The table surface and frame are made of wear-resistant materials that can withstand prolonged use and the pressure of cutting tools.

6. Drainage System: Some tables are designed with a drainage system to facilitate the cleaning of glass fragments and coolant produced during cutting.

7. Illumination and Auxiliary Tools: The table may be equipped with LED lighting and auxiliary tools, such as suction cups and clamps, to assist in the fixation and cutting of glass.

8. Automation Options: High-end glass cutting tables may integrate automated cutting systems that can connect with Computer-Aided Design (CAD) software to achieve automatic marking and precise cutting.

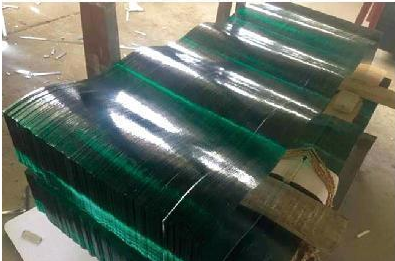

Glass cutting tables are widely used in industries such as construction, decoration, furniture, and advanced glass processing, and are essential equipment in the glass processing process.

A glass reducing desk is a specialised piece of tools designed for the specific and environment friendly reducing of glass, making sure a protected working environment. The desk elements a steady work floor made from substances with excessive flatness, which is critical for keeping the steadiness of the glass in the course of the slicing process. This diagram prevents any slicing deviations that may appear due to vibrations, thereby improving the accuracy of the cuts.

Safety is a paramount consideration in the format of these tables. They are geared up with protection safety units such as guards and emergency end buttons to protect the operator. Additionally, the adjustable top function caters to operators of various statures, which helps in lowering fatigue related with extended work periods. The sturdiness of the desk is ensured by means of the use of wear-resistant substances for each the floor and the frame, permitting it to face up to non-stop use and the strain exerted via reducing tools.

For ease of renovation and cleanliness, some glass slicing tables encompass a drainage gadget that aids in the disposal of glass fragments and coolant generated for the duration of cutting. Furthermore, these tables may also come with LED lighting fixtures and auxiliary equipment like suction cups and clamps, which are necessary for securing and slicing the glass effectively.

In the realm of high-end glass slicing tables, automation alternatives are available, which includes built-in computerized reducing structures that can interface with Computer-Aided Design (CAD) software. This permits automated marking and rather unique cutting. Such superior tables are vital in industries such as construction, decoration, furnishings making, and state-of-the-art glass processing, the place precision and effectivity are key to the manufacturing process.