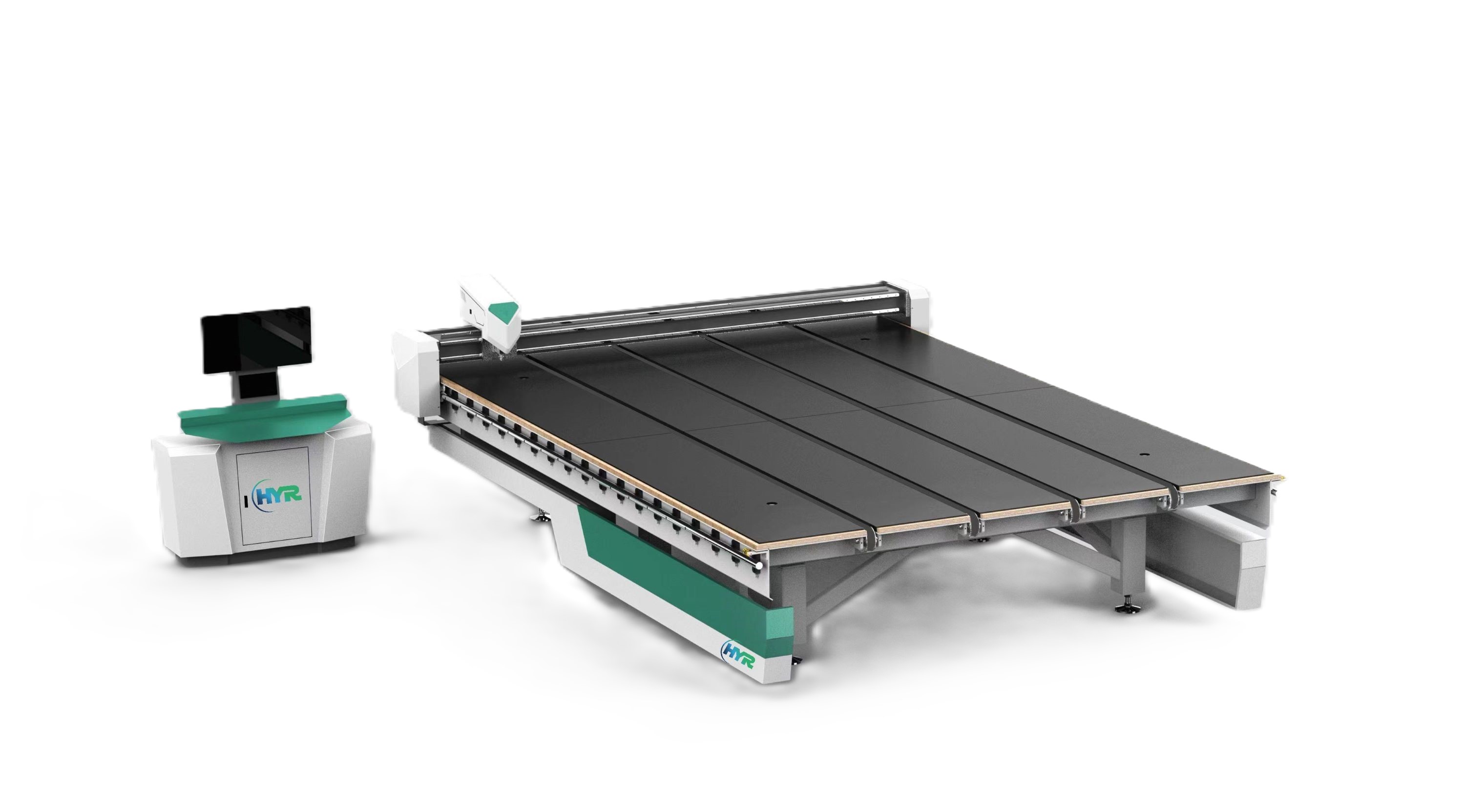

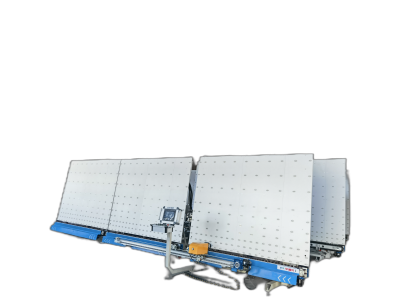

Glass Cutter With Grinder

Product performance

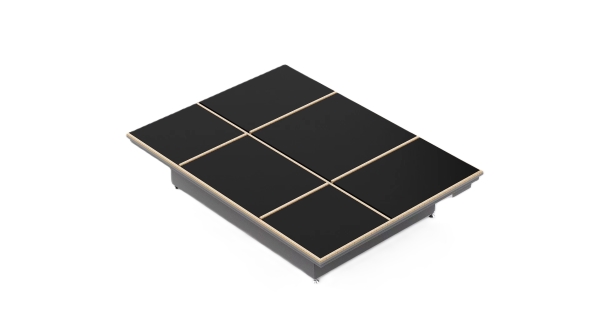

The design draws on the concept of German Industry 4.0, and realizes the automatic cutting process, information data and intelligent operation. The overall frame of the equipment adopts bridge steel technology, which is aged after welding, and the fuselage steel plate is milled out with a gantry mill, which has super strength and stability qualitative. Frame structure material is made of high manganese steel, high strength, no deformation, welding after aging treatment, good physical properties can be matched with bilateral grinding, four-edge grinding line production, glass does not fall, improve work efficiency.

Highlighting Features:

Seamless Automated Workflow

- Embrace cutting-edge automation that eradicates human error, slashes labor costs, and is powered by an intelligent cutting process.

- Benefit from a comprehensive data management system that provides instant production monitoring and control.

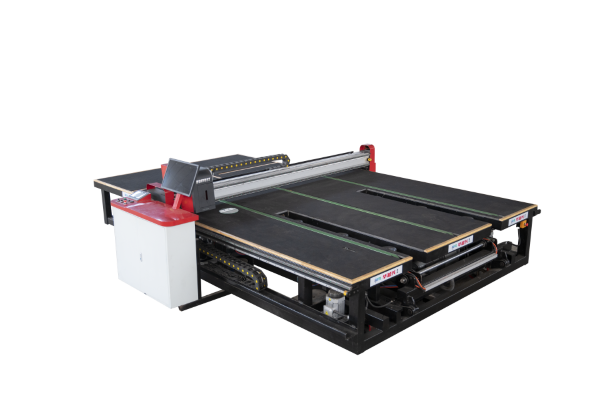

Unmatched Structural Integrity

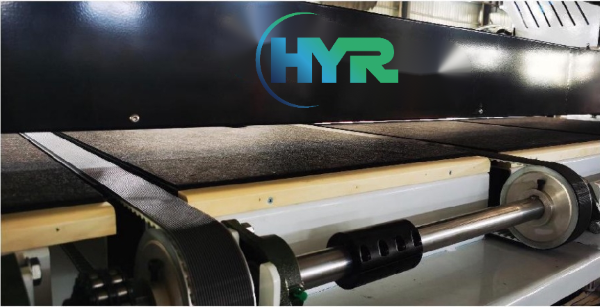

- Engineered with advanced bridge steel technology for unparalleled strength and resilience.

- Features a high-manganese steel frame that withstands heavy loads without deformation, thanks to its robust construction.

- Welded parts are treated for improved durability and extended lifespan.

Precision Cutting Technology

- Experience precision milling with a gantry mill that ensures the highest level of cutting accuracy for body steel plates.

- Designed for compatibility with bilateral and four-edge grinding lines, ensuring glass stability and preventing accidents.

Versatile Usage Across Industries

- Perfect for diverse sectors, including construction, automotive, home appliances, and kitchenware.

- Capable of processing a variety of glass types, from coated glass to mirrors and intricate handicrafts.

Effortless Operation

- Navigate with ease using an intuitive control panel that simplifies operation and allows for swift setup.

- Customize cutting patterns and dimensions to suit the unique specifications of any project with ease.

Product performance

The design draws on the concept of German Industry 4.0, and realizes the automatic cutting process, information data and intelligent operation. The overall frame of the equipment adopts bridge steel technology, which is aged after welding, and the fuselage steel plate is milled out with a gantry mill, which has super strength and stability qualitative. Frame structure material is made of high manganese steel, high strength, no deformation, welding after aging treatment, good physical properties can be matched with bilateral grinding, four-edge grinding line production, glass does not fall, improve work efficiency.

Technical Details:

Model | ACCURACY | APEED | MAX CUTTING SIZE | THICKNESS | POWER | POWER SUPPLY |

14033 | ≤±0.20mm/m | 0-220m/min | 14000mm×3300mm | 3-19mm | 70kw | 380v/50HZ |

6137 | ≤±0.20mm/m | 0-220m/min | 6100mm×3700mm | 3-19mm | 25kw | 380v/50HZ |

6133 | ≤±0.20mm/m | 0-220m/min | 6100mm×3700mm | 3-19mm | 25kw | 380v/50HZ |

5133 | ≤±0.20mm/m | 0-220m/min | 5100mm×3300mm | 3-19mm | 25kw | 380v/50HZ |

4228 | ≤±0.20mm/m | 0-220m/min | 4200mm×2800mm | 3-19mm | 18kw | 380v/50HZ |

2621 | ≤±0.20mm/m | 0-220m/min | 2600mm×2100mm | 3-19mm | 12kw | 380v/50HZ |

Remark: Special sizes can be customized | ||||||