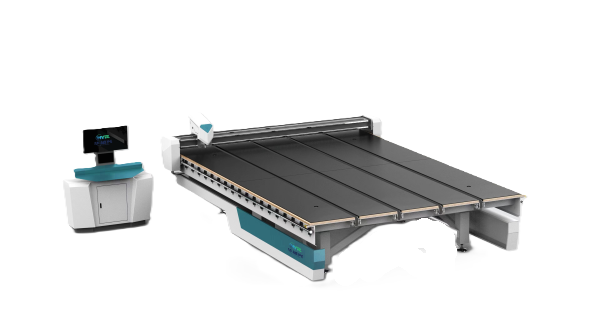

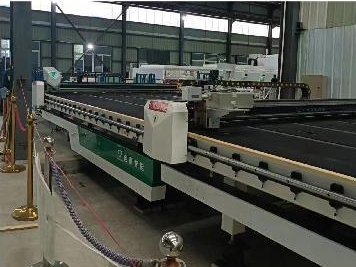

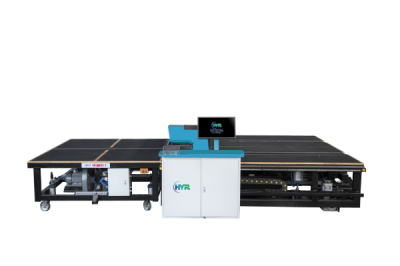

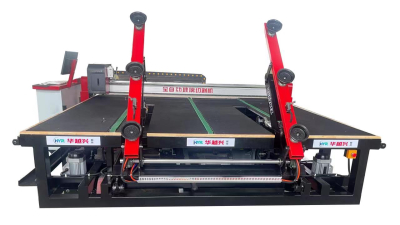

Three-In-One CNC Automatic Glass Cutting Line

The product's design is inspired by the principles of German Industry 4.0, facilitating an automated cutting process that is complemented by comprehensive information data management and intelligent operation systems. This integration of advanced technology ensures a seamless and efficient workflow.

For the equipment's framework, bridge steel technology is employed, with the steel plates undergoing a welding process followed by aging treatment. The body of the machine is then precision-milled using a gantry mill, resulting in a structure that boasts superior strength and stability, essential for reliable performance.

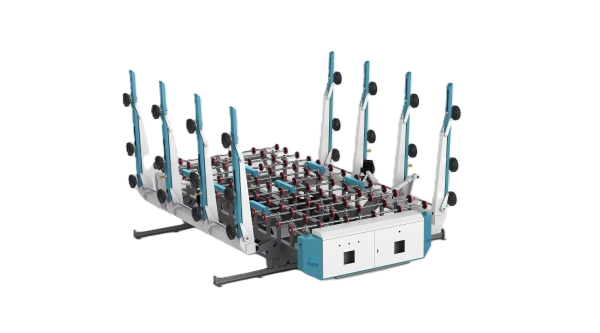

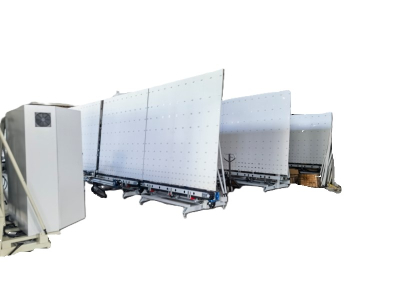

The material used for the frame structure is high manganese steel, renowned for its high strength and resistance to deformation. After welding, the material undergoes aging treatment to enhance its physical properties, making it suitable for bilateral grinding and four-edge grinding line production. This design not only prevents glass from falling but also significantly boosts work efficiency.

The product's graph is stimulated through the ideas of German Industry 4.0, facilitating an automatic slicing method that is complemented via complete statistics statistics administration and smart operation systems. This integration of superior science ensures a seamless and environment friendly workflow.

For the equipment's framework, bridge metal science is employed, with the metal plates present process a welding system accompanied through getting old treatment. The physique of the computing device is then precision-milled the usage of a gantry mill, ensuing in a shape that boasts foremost power and stability, quintessential for dependable performance.

The fabric used for the body shape is excessive manganese steel, famend for its excessive power and resistance to deformation. After welding, the fabric undergoes ageing therapy to beautify its bodily properties, making it appropriate for bilateral grinding and four-edge grinding line production. This graph now not solely prevents glass from falling however additionally notably boosts work efficiency.

MODEL | ACCURACY | APEED | MAX CUTTING SIZE | THICKNESS | POWER | POWER SUPPLY |

14033 | ≤±0.20mm/m | 0-220m/min | 14000mm×3300mm | 3-19mm | 70kw | 380v/50HZ |

6137 | ≤±0.20mm/m | 0-220m/min | 6100mm×3700mm | 3-19mm | 25kw | 380v/50HZ |

6133 | ≤±0.20mm/m | 0-220m/min | 6100mm×3700mm | 3-19mm | 25kw | 380v/50HZ |

5133 | ≤±0.20mm/m | 0-220m/min | 5100mm×3300mm | 3-19mm | 25kw | 380v/50HZ |

4228 | ≤±0.20mm/m | 0-220m/min | 4200mm×2800mm | 3-19mm | 18kw | 380v/50HZ |

2621 | ≤±0.20mm/m | 0-220m/min | 2600mm×2100mm | 3-19mm | 12kw | 380v/50HZ |

Remark :Special sizes can be customized | ||||||