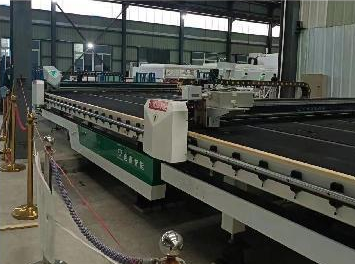

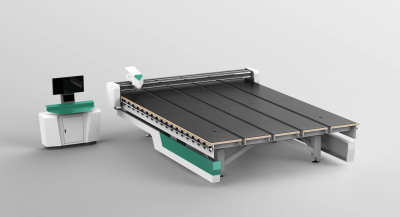

Fully Automatic Glass Cutting and Film Removal Machine

Product performance

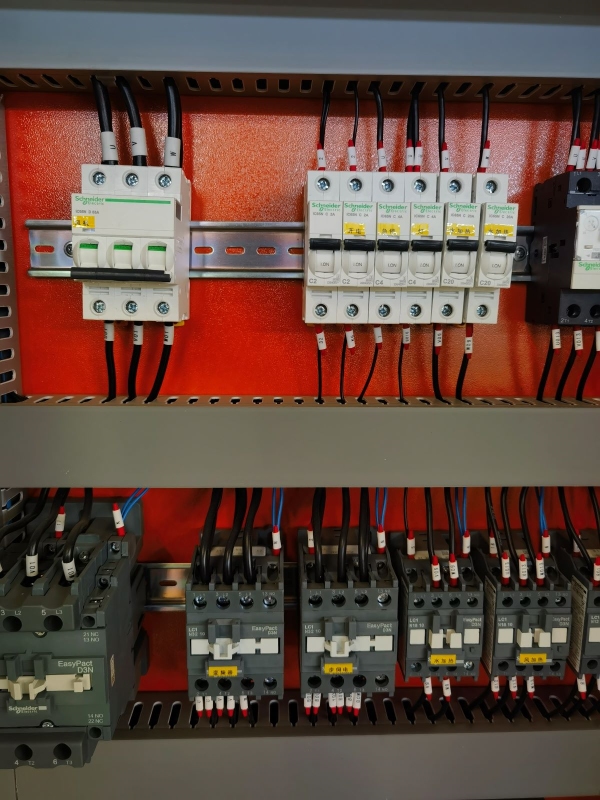

The design draws on the concept of German Industry 4.0, and realizes the automatic cutting process, information data and intelligent operation. The overall frame of the equipment adopts bridge steel technology, which is aged after welding, and the fuselage steel plate is milled out with a gantry mill, which has super strength and stability

Qualitative. Frame structure material is made of high manganese steel, high strength, no deformation, welding after aging treatment, good physical properties can be matched with bilateral grinding, four-edge grinding line production, glass does not fall, improve work efficiency.

Product Performance Overview:

This product's design is meticulously crafted, inspired by the forward-thinking concept of German Industry 4.0. It successfully incorporates an automatic cutting process that is seamlessly integrated with information data systems and intelligent operation protocols. The result is a cutting-edge machine that stands at the forefront of technological advancement in the industry.

The equipment's structural integrity is anchored by its overall frame, which is built using sophisticated bridge steel technology. Each joint is meticulously welded and then subjected to an aging process to ensure maximum durability and resilience. The body of the machine is precision-milled using a gantry mill, a process that not only enhances its aesthetic appeal but also confers upon it a superlative level of strength and stability, making it a reliable workhorse in various industrial settings.

The material used for the frame structure is high manganese steel, renowned for its exceptional strength and resistance to deformation. This choice of material guarantees that the equipment will maintain its structural integrity even under the most demanding conditions. The high manganese steel is further enhanced by an aging treatment post-welding, which refines its physical properties and ensures that the frame remains robust and unyielding.

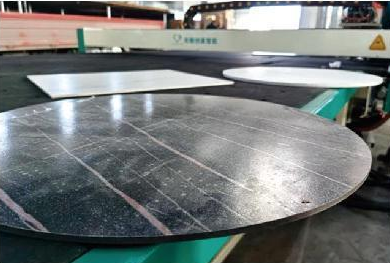

This robust construction is not just for show; it serves a practical purpose by allowing the machine to be compatible with bilateral grinding and a four-edge grinding line production processes. The design is thoughtful in its approach to maintaining the security of the glass during operation, ensuring that it does not fall and thereby improving the overall work efficiency of the production line.

In summary, the product's performance is characterized by its intelligent operation,自动切割 precision, and the unparalleled strength and stability of its frame. The use of high-quality materials and the implementation of advanced manufacturing techniques not only enhances the machine's longevity but also significantly contributes to the enhancement of work efficiency in glass processing operations.

Different models of machines for different cutting needs

Model | ACCURACY | APEED | MAX CUTTING SIZE | THICKNESS | POWER | POWER SUPPLY |

14033 | ≤±0.20mm/m | 0-220m/min | 14000mm×3300mm | 3-19mm | 70kw | 380v/50HZ |

6137 | ≤±0.20mm/m | 0-220m/min | 6100mm×3700mm | 3-19mm | 25kw | 380v/50HZ |

6133 | ≤±0.20mm/m | 0-220m/min | 6100mm×3700mm | 3-19mm | 25kw | 380v/50HZ |

5133 | ≤±0.20mm/m | 0-220m/min | 5100mm×3300mm | 3-19mm | 25kw | 380v/50HZ |

4228 | ≤±0.20mm/m | 0-220m/min | 4200mm×2800mm | 3-19mm | 18kw | 380v/50HZ |

2621 | ≤±0.20mm/m | 0-220m/min | 2600mm×2100mm | 3-19mm | 12kw | 380v/50HZ |

Remark :Special sizes can be customized | ||||||