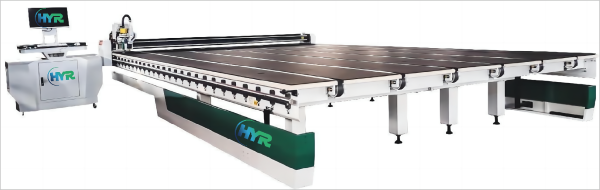

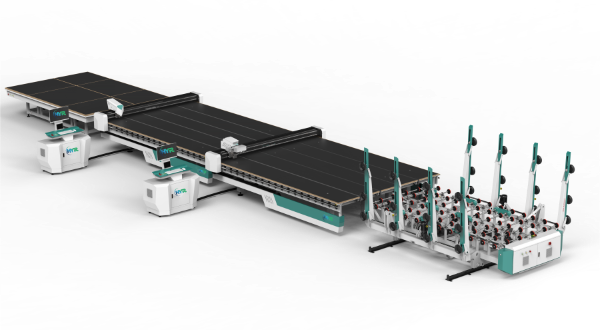

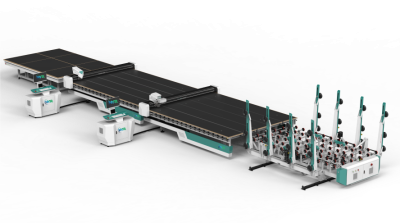

Low-E Glass Film Removal Cutting Machine

Fundamental Operation Principle:

The operation starts with the conveyor belt system transporting the glass to be cut to the worktable. The glass's position is then automatically detected and recorded using an optical scanning system. Subsequently, the servo motor within the film removal mechanism powers the gear, facilitating a full 360° rotation of the grinding wheel. This rotation is directly driven by the connected servo motor, which manipulates the grinding wheel to rotate and effectively strip the film. The machine then moves in the X and Y directions, utilizing the diamond cutting wheel at the cutting head of the cutter box to remove the film and proceed with cutting the substrate.

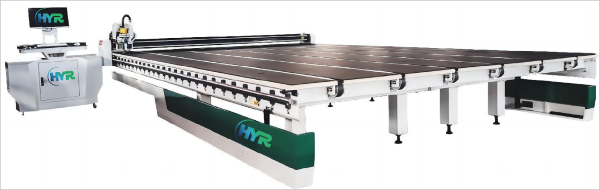

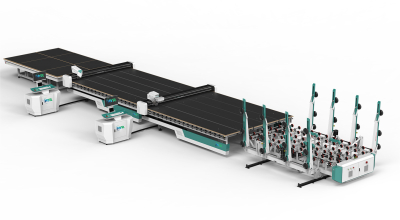

Fundamental Operation Principle:

The operation begins with the conveyor belt machine transporting the glass to be reduce to the worktable. The glass's function is then robotically detected and recorded the usage of an optical scanning system. Subsequently, the servo motor inside the movie elimination mechanism powers the gear, facilitating a full 360° rotation of the grinding wheel. This rotation is at once pushed through the related servo motor, which manipulates the grinding wheel to rotate and efficiently strip the film. The desktop then strikes in the X and Y directions, making use of the diamond reducing wheel at the reducing head of the cutter field to do away with the movie and proceed with reducing the substrate.