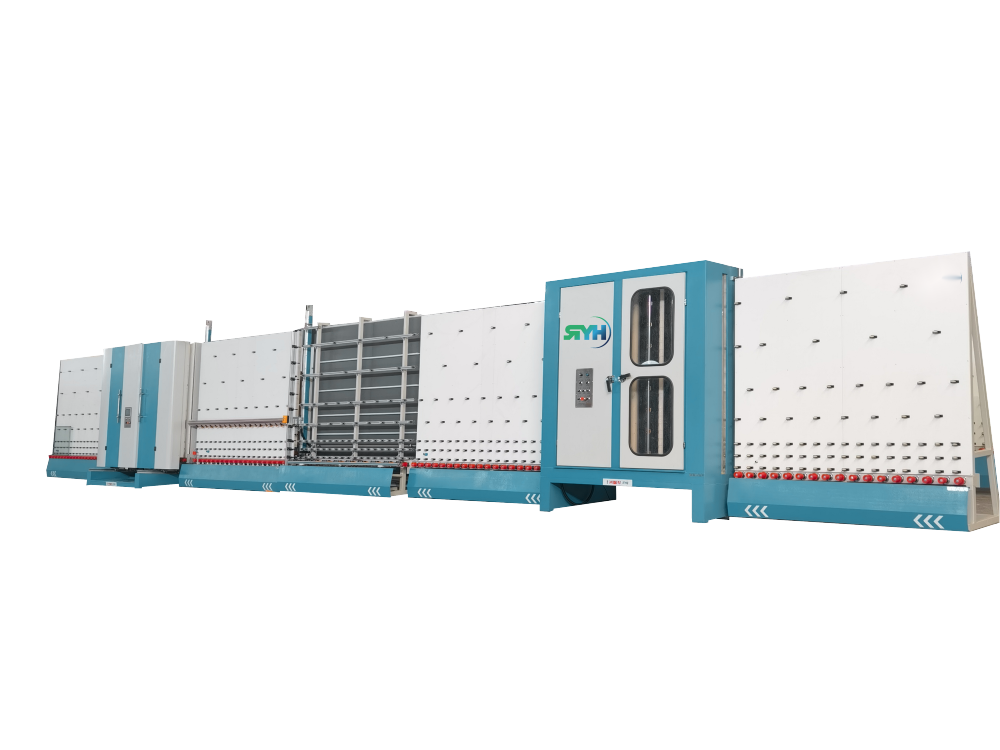

Fully Automatic Warm Edge Insulating Glass Production Line

MAIN FEATURES

1. Can achieve a variety of sizes of rectangular insulating glass glue continuity, glue efficiency is high, stable quality;

The machine is composed of 4 sections, the first section can pre-store a piece of glass, the fourth section can wait for the film, the efficiency is 20% higher than other manufacturers;

2. The common function is the button switch design, the operation is simpler, convenient to train employees, the detailed parameters can be operated by the touch film screen;

3. The side of the glue filled no bubbles, full corner, no manual trimming;

4. The world famous brand servo control system, stable performance;

5. Accurate synchronous belt transmission system to ensure the smooth running of glass without adhesive;

6. Unique glue amount automatic alarm device and automatic glue discharge function.

7. Can be customized according to customer requirements, reverse and various sizes of equipment.

8. The inlet and outlet are made of all-aluminum structure, waterproof, more durable

KEY CHARACTERISTICS:

1. Capable of achieving consistent glue application for various sizes of rectangular insulating glass, ensuring high efficiency and consistent quality. The workstation is divided into four sections, with the first section allowing for the pre-loading of a glass pane and the fourth section designed for film application, offering a 20% increase in efficiency compared to competitors.

2. A standout feature is the easy-to-use button swap design, simplifying operations and facilitating staff training. Precise parameters can be set via the intuitive touch screen interface.

3. Ensures bubble-free glue filling, complete corner coverage, and eliminates the need for manual trimming.

4. Equipped with a globally renowned servo control system for reliable performance.

5. Utilizes an accurate synchronous belt transmission system to guarantee smooth glass movement without adhesive interference.

6. Features a unique glue quantity monitoring system with automatic alarms and an automatic glue discharge function.

Additionally, the machine can be customized to meet specific customer requirements, offering reversible functionality and the ability to handle various equipment sizes.

Technical Details:

Voltage | 3P/380V/50Hz | Insulating glass thickness | 12-60mm |

Total power | 14KW | Coating depth | 3-15mm |

Transfer speed | 0-50m/min | Aluminum frame width | 6-27mm |

Min.glass. size | 300×180mm | Coating rate | 5-40m/min

|

Max.Glass. Size | 4000×2500mm | Hydraulic pressure | <100kg/cm² |

Overall dimension | 11250×2500×3350mm | Air source | 0.6-0.8MPa |