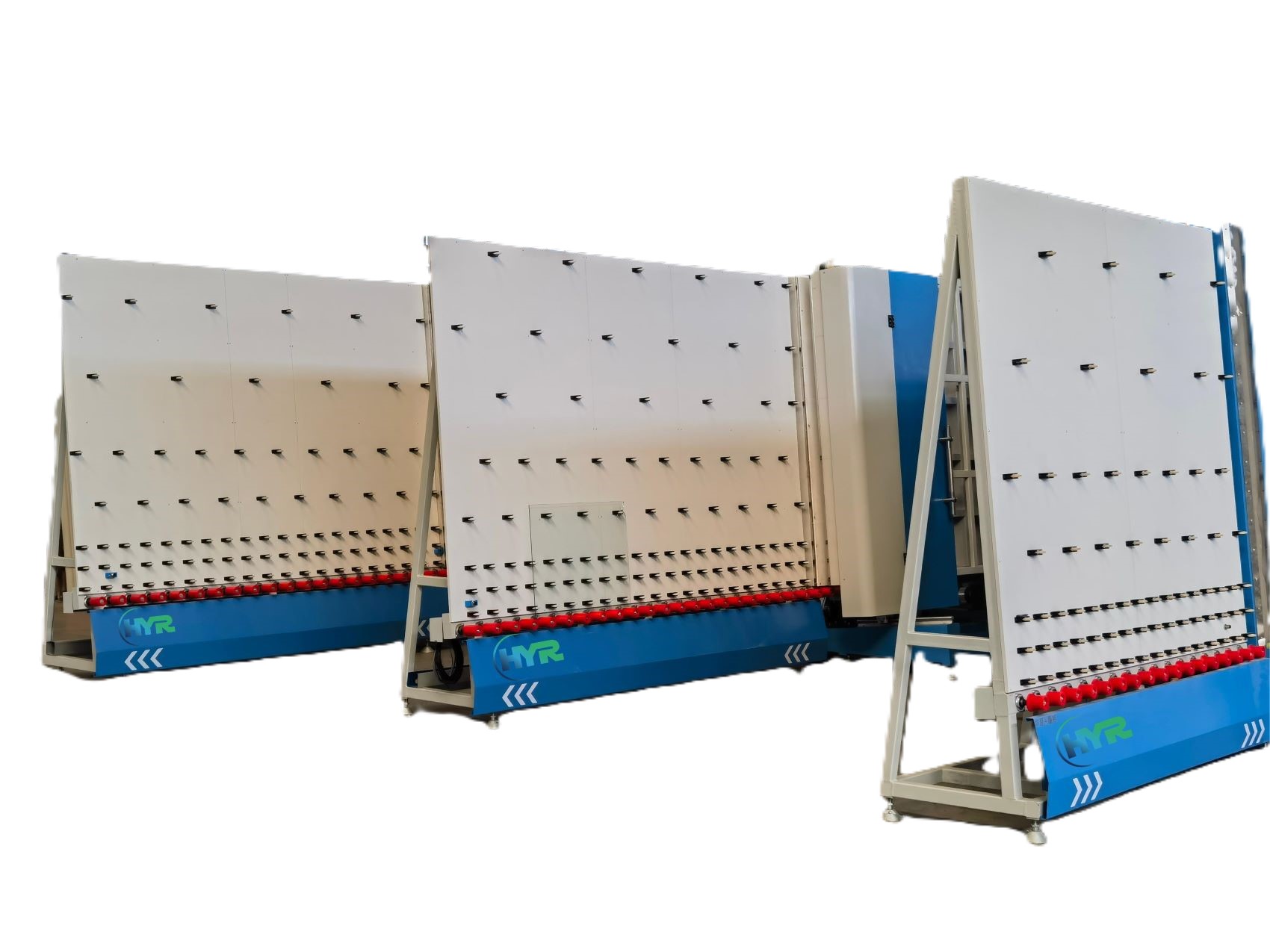

Customizable Insulating Glass Production Line Near Me

MAIN FEATURES

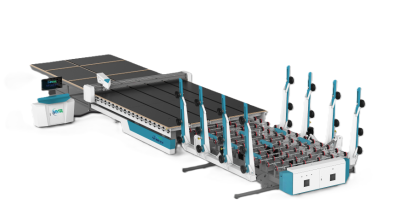

Wash area and wash areas using stainless steel and corrosion-resistant materials, three pairs of independent operation brush, brush spacing is adjustable, using CNC automation program runs;

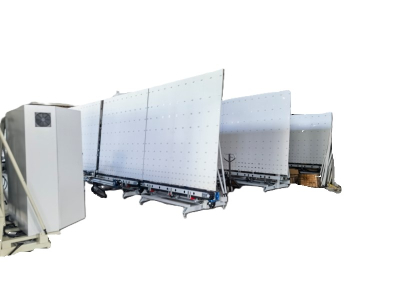

1.Can produce double glass and three glass hallow glass, long glass, long glass can be secondary plate pressure; Automatic or manual operation, easy to operate;

2.Plate pressure with exclusive point adjustment technology, and with automatic plate presure maintenance function;

3.Circulating hot air drying section, improve the cleaning speed, making it dry reduce noise; All use high-density soft brush, can clean all kind of LOW-E glasses, coated glasses;

4.The machine is equipped with an advanced intelligent cleaning system;

5.Customizable forward and reverse direction of the device according to the direction of travel of the glass.

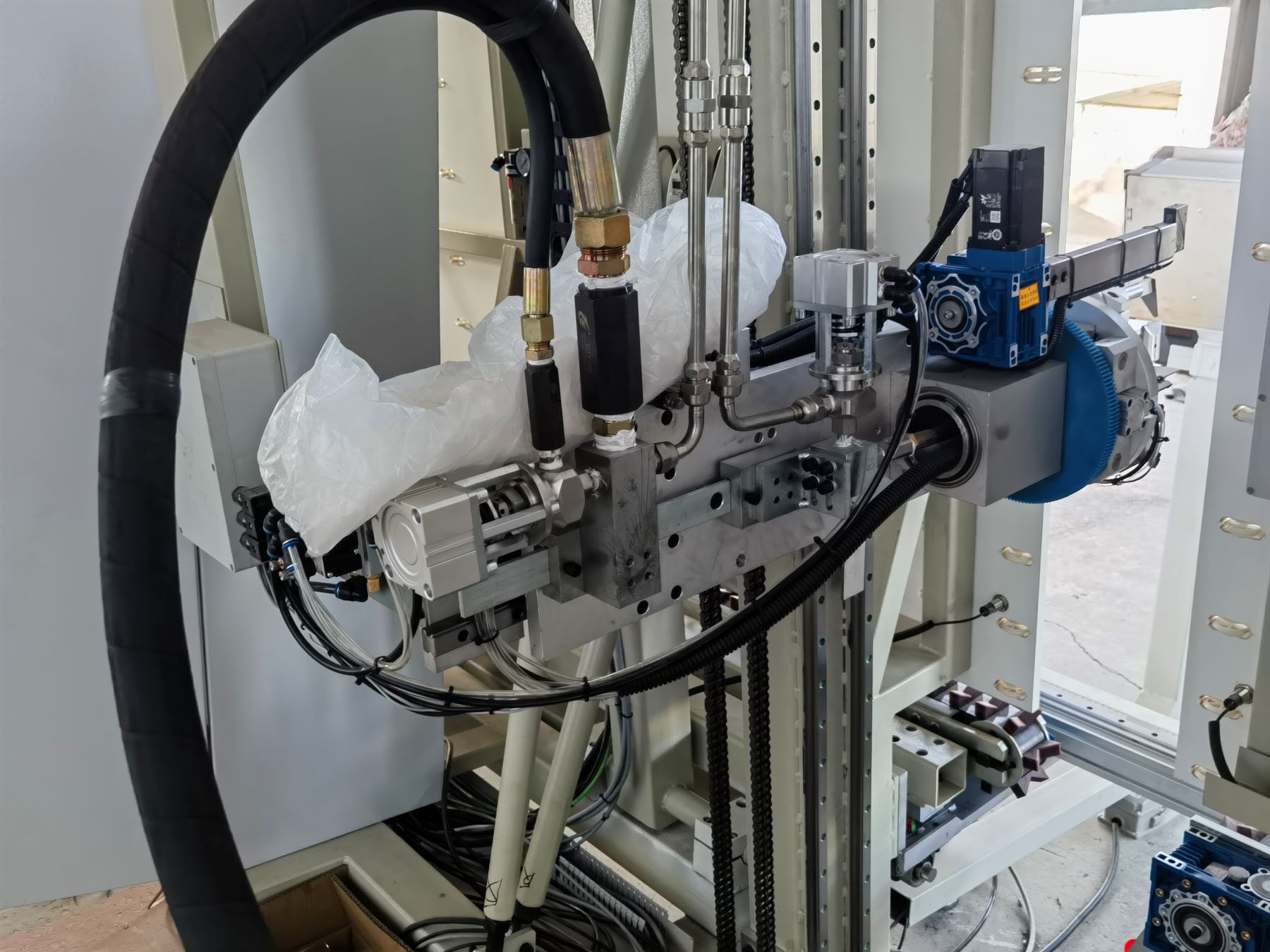

Customizable in board inflation function equipment, PW-C(external closure inflation), PW(external closure).

1.Durable and Precise Washing Section: The washing section is meticulously constructed from stainless steel and corrosion-resistant materials, ensuring longevity and reliability. It is equipped with three units of brushes that can be operated independently and adjusted for superior spacing. These brushes are powered by using CNC automatic programming, which ensures a excessive degree of precision and effectivity in the cleansing process.

2.Adaptable Glass Production Capabilities: This machine is engineered to manufacture both double-glazed and triple-glazed insulating glass, with the added ability to process long glass panels. It gives the comfort of working in both computerized or guide mode, accommodating exceptional person preferences and manufacturing requirements. The urgent plate points a proprietary factor adjustment technology, which is supported with the aid of an computerized upkeep feature to make sure the urgent mechanism stays in top condition.

3.High-Efficiency Drying and Intelligent Cleaning: A key component of the machine is the circulating hot air drying section, which significantly boosts cleaning efficiency, ensures complete drying, and operates quietly. The computer is equipped with high-density tender brushes that are ideal for cleansing a range of glass types, together with LOW-E and covered glass. An superior sensible cleansing gadget is embedded inside the computer to supply finest performance.

4.Customizable Travel Direction and Inflation Options: The machine's travel direction is customizable, enabling it to operate in either forward or reverse, which is particularly useful for accommodating the specific path of the glass. The equipment can be tailored to incorporate a board inflation option, offering two distinct setups: the PW-C model featuring external sealed inflation, and the PW model with additional external sealing. This feature enhances the machine's flexibility and capability to cater to various production settings.

Technical indicators

Voltage | 3P/380V/50Hz | Maximum glass size | 2000×2500mm |

Total power | 28KW | Maximum thickness of insulating glass | 60mm |

Washing speed | 0-13m/min | Air consumption | 1m³/min |

Maximum working speed | 50m/min | Dimension | 18200×2800×2920mm |

Minimum glass size | 300×450mm |