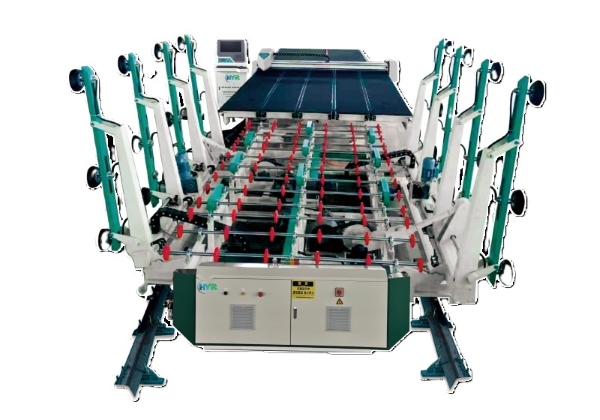

Multifunctional Glass Cutting Machine

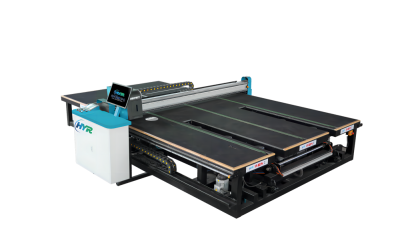

Basic principle:

The fundamental working precept is that the reduce glass is transported to the work desk via the conveyor belt, the function of the glass is mechanically recorded via the photoelectric scanning system, and then the servo motor on the movie elimination system drives the equipment to rotate to acquire 360° rotation of the grinding wheel, and the immediately related servo motor is related thru the grinding wheel

Drive the grinding wheel to rotate so as to acquire the impact of eliminating film, and pass alongside the X route and Y route respectively to get rid of movie via the slicing head of the diamond cutter wheel on the cutter box, and reduce the substrate.

Product Advantages:

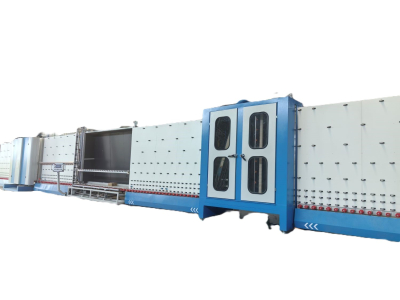

A glass cutting table is a specialized piece of equipment designed for the precise and efficient cutting of glass, ensuring a safe working environment. The table features a stable work surface made from materials with high flatness, which is crucial for maintaining the stability of the glass during the cutting process. This design prevents any cutting deviations that might occur due

to vibrations, thereby enhancing the accuracy of the cuts.

Safety is a paramount consideration in the design of these tables. They are equipped with safety protection devices such as guards and emergency stop buttons to safeguard the operator. Additionally, the adjustable height feature caters to operators of varying statures, which helps in reducing fatigue associated with prolonged work periods. The durability of the table is ensured by the use of wear-resistant materials for both the surface and the frame, allowing it to withstand continuous use and the pressure exerted by cutting tools.

For ease of maintenance and cleanliness, some glass cutting tables include a drainage system that aids in the disposal of glass fragments and coolant generated during cutting. Furthermore, these tables may come with LED lighting and auxiliary tools like suction cups and clamps, which are essential for securing and cutting the glass effectively.

In the realm of high-end glass cutting tables, automation options are available, including integrated automated cutting systems that can interface with Computer-Aided Design (CAD) software. This enables automatic marking and highly precise cutting. Such advanced tables are indispensable in industries such as construction, decoration, furniture making, and sophisticated glass processing, where precision and efficiency are key to the manufacturing process.

Equipment composition mechanism

Automatic cutting machine: composed of frame mechanism, beam mechanism, table mechanism, tool head mechanism, removing film device, grinding wheel device, conveying mechanism, photoelectric scanning positioning mechanism, electrical control system