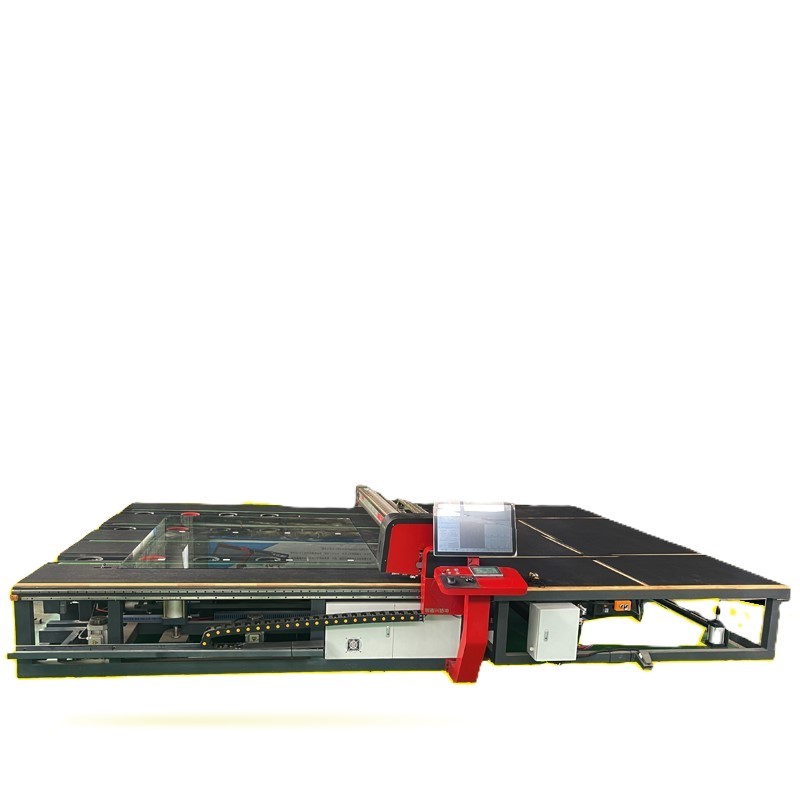

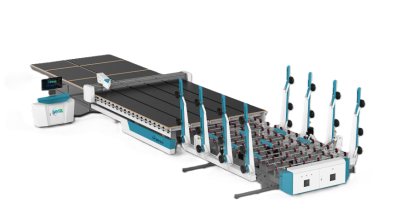

Glass Cutting Machine With Automatic Loading Table

The glass cutting machine equipped with an automatic loading table is a highly automated piece of equipment that integrates a variety of advanced features and functions to enhance production efficiency and cutting accuracy while reducing labor intensity. The machine's key features include an automatic loading table that places glass sheets onto the cutting table without manual intervention, saving time and labor. It also boasts a high-precision cutting system with linear guides and servo motors for stable and precise cuts, an intelligent control system that interfaces directly with CAD software for accurate cutting path planning, and an intuitive human-machine interface for easy parameter setting and process monitoring.

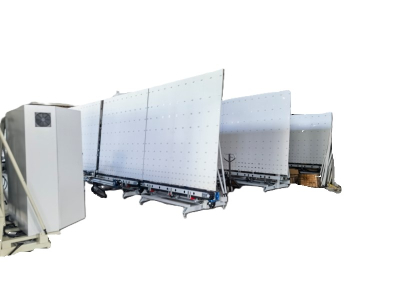

In terms of functionality, the machine offers automatic alignment to ensure precise pattern matching with the glass sheets, a quick tool change system for adapting to different glass thicknesses, and versatile cutting capabilities for straight lines, curves, circles, and complex patterns. Safety features such as emergency stop buttons and protective covers are in place to ensure operator safety. Additionally, the machine may include an automatic cleaning system for debris and coolant removal, an automatic unloading system for neatly stacking finished glass pieces, and energy-saving designs to reduce energy consumption and waste.

Suited for large-scale glass processing industries, the glass cutting machine with an automatic loading table significantly boosts production efficiency, reduces production costs, and ensures product quality stability. It also records production data for subsequent analysis and traceability, aiding in the optimization of production processes and the enhancement of product quality.

The glass slicing laptop outfitted with an computerized loading desk is a tremendously computerized piece of tools that integrates a range of superior elements and functions to beautify manufacturing effectivity and slicing accuracy whilst decreasing labor intensity. The machine's key elements consist of an computerized loading desk that locations glass sheets onto the reducing desk except guide intervention, saving time and labor. It additionally boasts a high-precision reducing device with linear courses and servo motors for secure and unique cuts, an sensible manage machine that interfaces at once with CAD software program for correct reducing course planning, and an intuitive human-machine interface for effortless parameter placing and procedure monitoring.

In phrases of functionality, the computer provides computerized alignment to make certain particular sample matching with the glass sheets, a rapid device trade device for adapting to exclusive glass thicknesses, and versatile reducing competencies for straight lines, curves, circles, and complicated patterns. Safety facets such as emergency quit buttons and defensive covers are in region to make sure operator safety. Additionally, the computing device may also consist of an automated cleansing device for particles and coolant removal, an automated unloading device for neatly stacking completed glass pieces, and energy-saving designs to limit power consumption and waste.