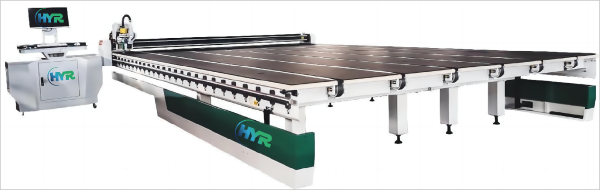

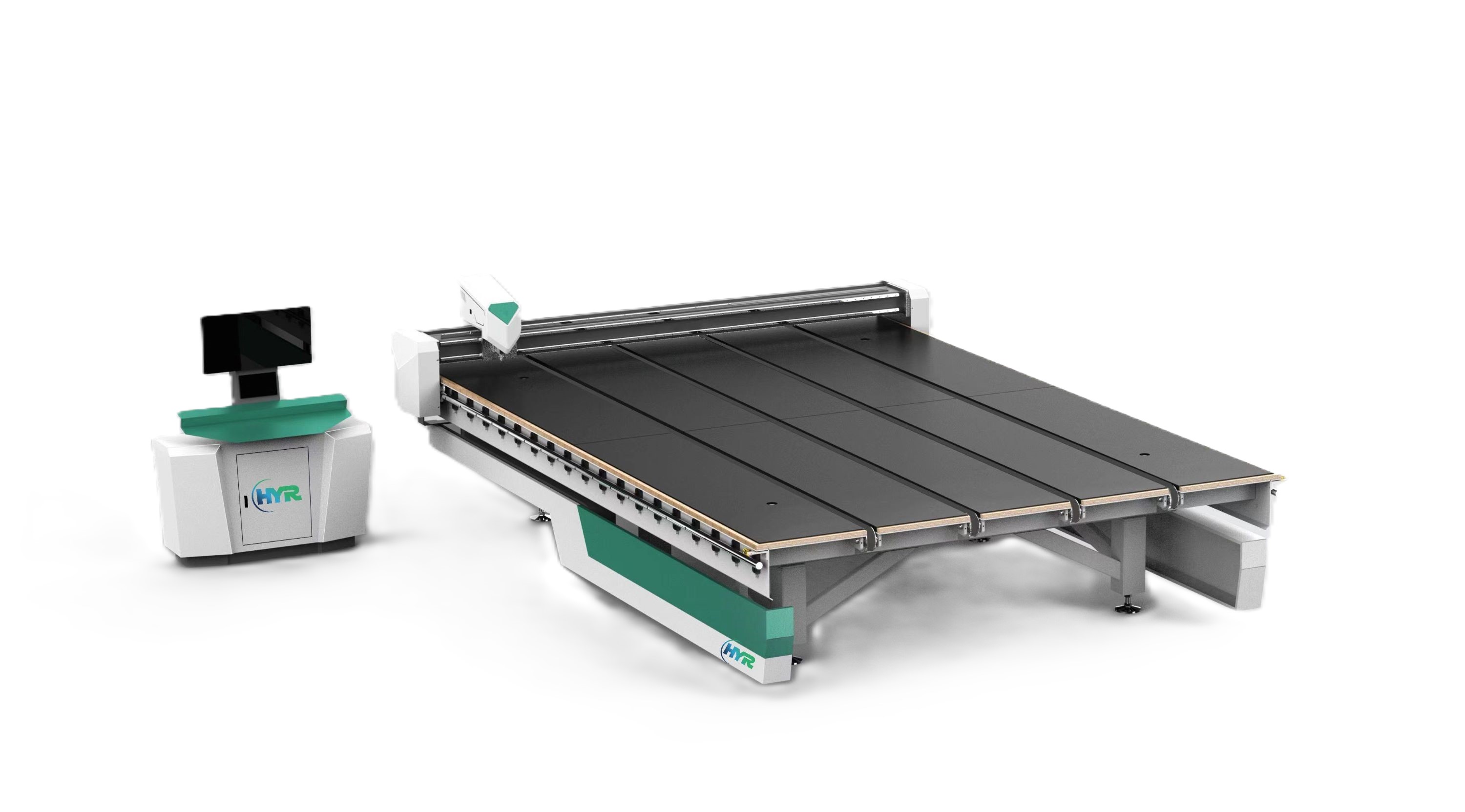

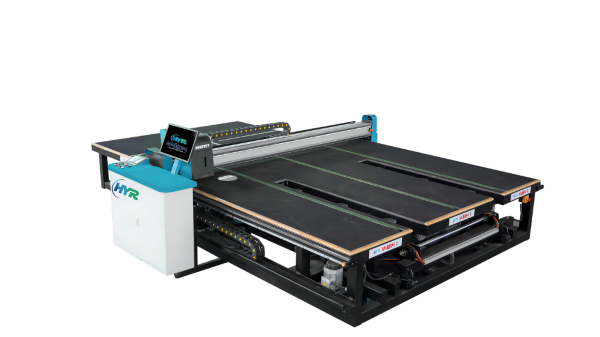

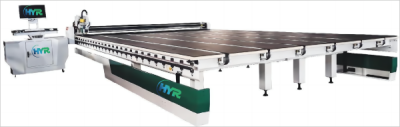

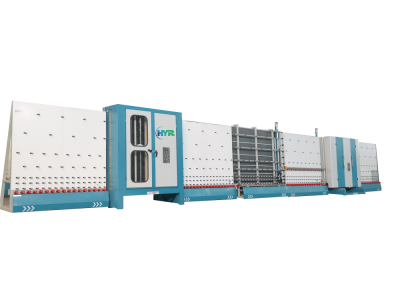

Automatic Repair Wheel Low-E Glass Cutting Machine

Basic principle

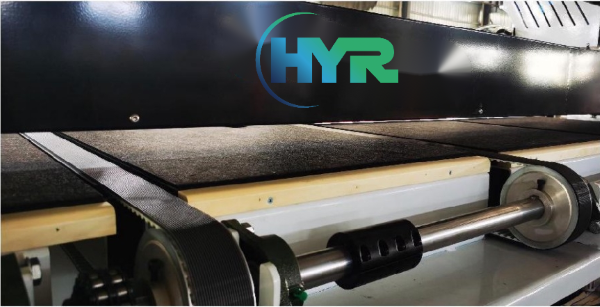

The basic working principle is that the cut glass is transported to the work table by the conveyor belt, the position of the glass is automatically recorded through the photoelectric scanning system, and then the servo motor on the film removal device drives the gear to rotate to achieve 360° rotation of the grinding wheel, and the directly connected servo motor is connected through the grinding wheel

Drive the grinding wheel to rotate so as to achieve the effect of removing film, and move along the X direction and Y direction respectively to remove film through the cutting head of the diamond cutter wheel on the cutter box, and cut the substrate.

The simple working precept is that the reduce glass is transported to the work desk by means of the conveyor belt, the function of the glass is robotically recorded via the photoelectric scanning system, and then the servo motor on the movie elimination gadget drives the equipment to rotate to gain 360° rotation of the grinding wheel, and the without delay linked servo motor is linked thru the grinding wheel

Drive the grinding wheel to rotate so as to gain the impact of eliminating film, and cross alongside the X route and Y course respectively to do away with movie via the reducing head of the diamond cutter wheel on the cutter box, and reduce the substrate.

Equipment composition mechanism

Automatic cutting machine: composed of frame mechanism, beam mechanism, table mechanism, tool head mechanism, removing film device, grinding wheel device, conveying mechanism, photoelectric scanning positioning mechanism, electrical control system